Cell & Gene Therapy Insights is an online, open-access, peer-reviewed journal dedicated to the interdisciplinary exploration and advancement of cell and gene therapy. With a translational focus, we connect innovative research to practical clinical applications, providing valuable insights into one of biotechnology’s fastest-evolving fields.

We address the key challenges and latest developments across advanced therapies, publishing original research articles, expert reviews, commentary, clinical trial reports, and more. Visit the Cell & Gene Therapy Insights Journal page for our complete collection.

Our popular webinar series provides expert-led discussions on important developments and methodologies in the field, designed to support ongoing professional growth.

Explore our specialised channels, including detailed coverage of critical areas like the cell and gene supply chain, for targeted insights into manufacturing, logistics, and regulatory frameworks essential to therapy commercialisation.

Learn more about our journal’s mission and publishing criteria by visiting our aims and scope.

Sign-up for free to gain unlimited access to our extensive library of articles, webinars, podcasts, news, and interviews, and stay at the forefront of cell and gene therapy innovation.

If you’re interested in working with us, from sponsoring articles to webinars and more, view the media kit to find out more.

June 2025

Upcoming webinars

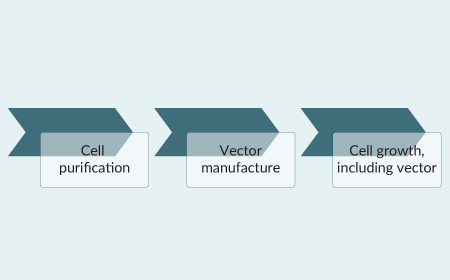

Strategic human raw material selection for cell therapy manufacturing

Cell therapy clinical translation: ensuring speed to clinic while mitigating risk

Exploring scalable, data-driven AAV manufacturing to achieve high yield and quality across serotypes

Lessons learned from an end-to-end digitization journey for advanced therapy workflows

Streamline disease modeling and therapeutic discovery with targeted viral vectors

Commercialization of CAR-T therapy in New Zealand: clinical insights & scalable manufacturing

Latest Articles

Navigating non-DEHP legislation while protecting cryopreserved cord blood inventories during regulatory transitions

Manufacturing and clinical development strategies to expand access to CAR-T cell therapy for patients in India

Reference standards for autologous products: material is not immaterial

IMAPAC Biologics World Korea 2025

Achieving high-titer rAAV production with significantly reduced encapsidated host cell DNA

Exploring asprosin: how AAV vectors are advancing hormone research

Rewriting the code: examining the promise and responsibility of gene editing

Targeting T cells in vivo: advances in non-viral gene delivery and clinical applications