Cell & Gene Therapy Insights is an online, open access, peer-reviewed journal with an interdisciplinary, translational focus on all aspects of the cell and gene therapy field.

Cell & Gene Therapy Insights addresses the important challenges and advances in advanced therapies, publishing original research, reviews, commentary articles, clinical trial reports, and much more. You can find more information about our aims and scope here.

Sign-up for free for unlimited access to all of our articles, webinars, podcasts, news, interviews, and more.

April 2025

Upcoming webinars

To 1000L and beyond: streamlining AAV manufacturing with transfection complex stabilization

Leisha Kopp, Mason Bonitz

3 June

in 5

Days

Optimizing for faster quality control in cell therapies: leveraging rapid detection methods

Srinath Kashi Ranganath

5 June

in 7

Days

Leveraging fluid dynamics characterization to accelerate cell therapy product development

Hamza Patel, Tom Heathman

10 June

in 12

Days

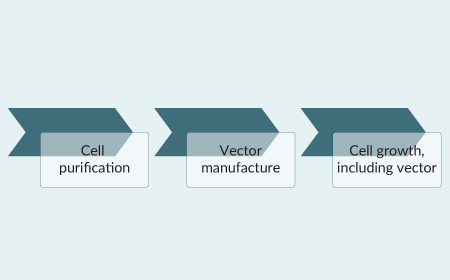

AAV production and purification: key steps from design to GMP readiness

G Ganjam, F Leseigneur, E Jackson-Holmes

11 June

in 13

Days

Non-viral GMP manufacturing for engineered cells at clinical and commercial scale

Leif Anderson, Chris Abraham

12 June

in 14

Days

Combining CRISPR and transposon-based technologies for improved sdAb-based CAR-T therapies

Begoña Diez Cabezas, Juan Roberto Rodriguez-Madoz

17 June

in 19

Days

Latest Articles

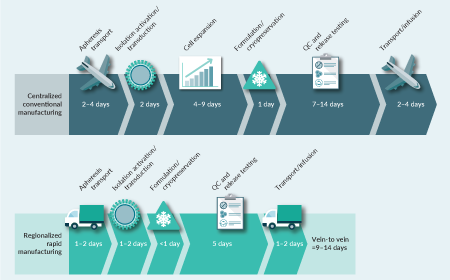

Full speed ahead: how rapid CAR-T manufacturing can shape the cell therapy landscape

Mackenzie Lieberman, Kathryn Henckels

29 May

Why choose a modular, automated approach to autologous CAR T manufacturing?: INFOGRAPHIC

28 May

Revolutionizing non-viral gene delivery with silicon-stabilized LNPs

Suzanne Saffie-Siebert

20 May

Efficient AAV purification: resin reuse and scalable polish method

Duncan Dulac

19 May

Optimizing upstream processing to improve consistency and scalability in viral vector production

Katerina Rigaki

19 May

Next-gen immunotherapy: a guide for CGT developers

Alex Sargent

9 May

Exploring innovations in AAV upstream processing to advance gene therapy development

Hao Liu

8 May

Register for Bioconjugation Insights

7 May

Essential equipment for advancing cell and gene therapy: innovations in incubation, monitoring, and cold storage

Tia Harmon

7 May