Biopreservation and cold chain biologistics risk points in the cell and gene therapy workflow

Cell & Gene Therapy Insights 2020; 6(08), 1363–1380

10.18609/cgti.2020.150

Introduction

The current state of regenerative medicine is a transformational period for cell and gene therapies. In addition to Novartis’ Kymriah®, Kite Pharma’s Yescarta® and Tecartus™, Spark’s Luxturna®, AveXis’ Zolgensma®, and bluebird bio’s Zynteglo® blazing the commercialization trail, there are over one thousand Phase 1, 2, and 3 cell and gene therapies (CGT) in pipeline development [1]Alliance for Regenerative Medicine Annual Report & Sector Year in Review: 2019.. Although this bodes well for patients, clinicians, industry, and investors, some unique aspects of cell- and gene-based therapies versus traditional pharmaceuticals or biopharma has highlighted the myriad of “new” manufacturing, clinical, and commercialization, challenges our industry now faces [2]Bersenev A, Kili S. Management of ‘out of specification’ commercial autologous CAR-T cell products. Cell Gene Ther. Ins. 2018; 4(11): 1051–8., [3]Chen LN, Collins-Johnson N, Sapp N, Pickett A, West K, Stroncek DF, Panch SR. How do I structure logistic processes in preparation for outsourcing of cellular therapy manufacturing? Transfusion 2019; 59: 2506–18. . Independently, each one of these challenges presents its own unique set of risks. Furthermore, when lined up in sequence and aggregated together in the manufacturing chain, if each portion is not optimized and risk-mitigated, the subsequent impact to the CGT product may be a compounding of the risks; and the sum total of all parts of the workflow will suffer. These beginning-to-end manufacturing risk points warrant appropriate assessment, and they are recommended to be addressed with the same diligence and priority as the therapies themselves, if the promise of Regenerative Medicine is to be fully realized. Fortunately, much has been learned regarding optimization of a number of key critical process parameters (CPP), and those looking to improve these parameters can leverage what has already been learned. This overview represents targeted lessons learned based on numerous experiences with CGT partners. Although intended to share feedback from experiences that may not always be detailed in the literature, it is not intended to address every aspect of the CGT workflow.

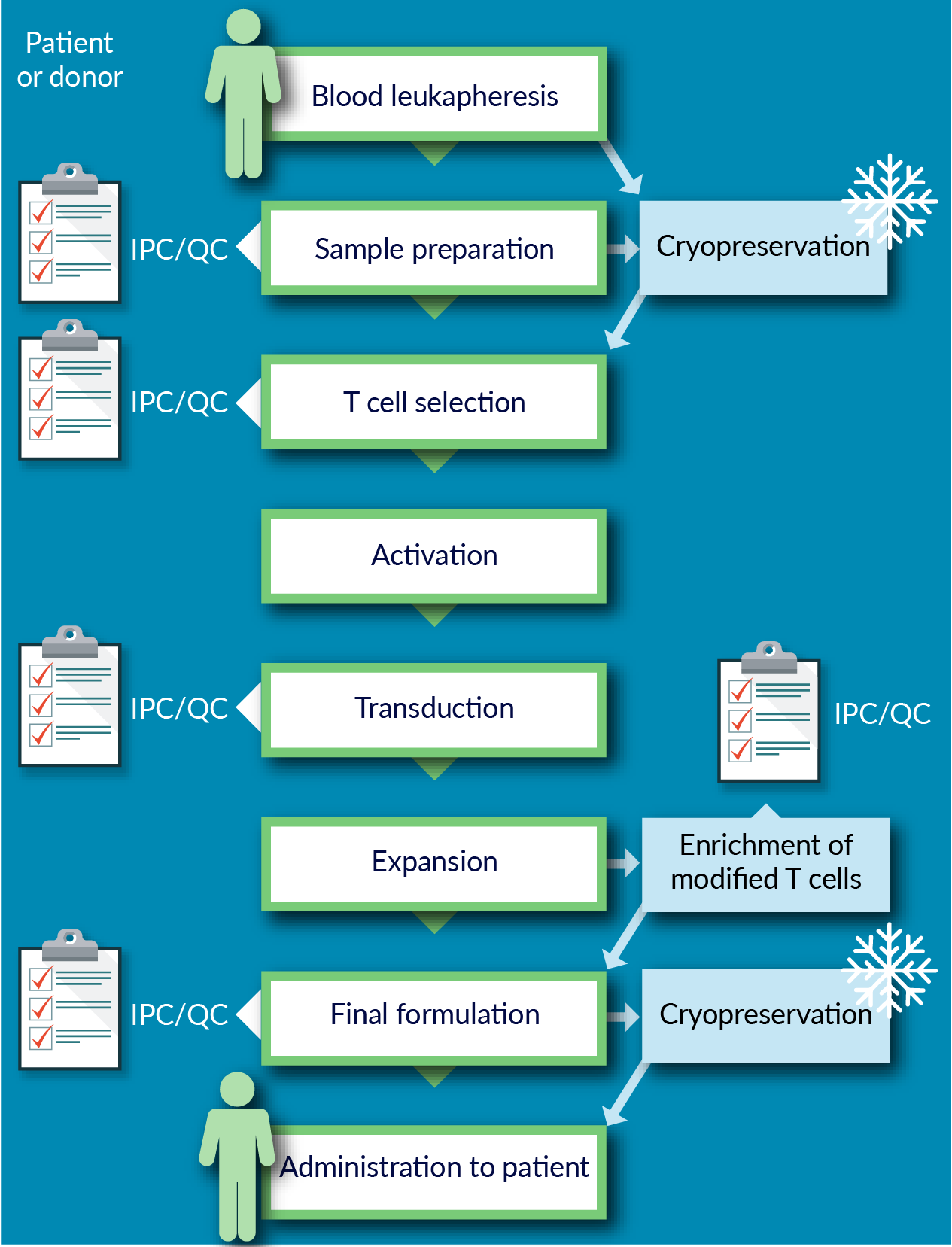

Representative cell immunotherapy workflow

Figure 1

In common CGT manufacturing workflows, starting source material is obtained; and then is processed, selected, and/or isolated. Often, the material undergoes a biopreservation step (cryopreservation or hypothermic preservation), and transported to a manufacturing facility; where activation, transduction, expansion, and/or final formation take place, before additional transport/storage for clinical application. This workflow highlights several biopreservation and biologistics areas where CGT may be challenged:

- Ensuring high quality starting material;

- Optimizing viable functional recovery, and minimizing variability and risk, in process development throughout the workflow chain;

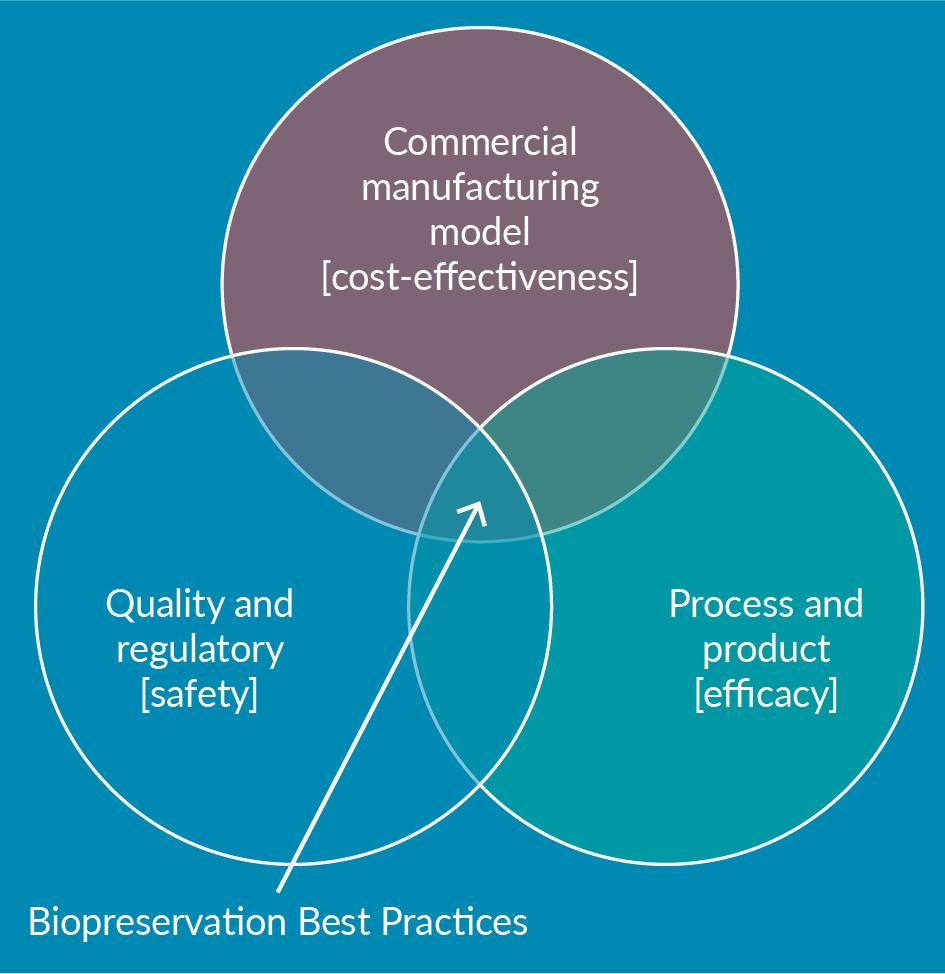

- Determining appropriate conditions for source material, intermediates, and final product – non-frozen or frozen (and, optimizing the biopreservation steps by utilizing Biopreservation Best Practices [5]Hawkins BJ, Abazari A, Mathew AJ. Biopreservation Best Practices for regenerative medicine GMP manufacturing & focus on optimized biopreservation media. Cell Gene Ther. Ins. 2017; 3(5): 345–58. Hawkins BJ, Abazari A, Mathew AJ. Biopreservation Best Practices for regenerative medicine GMP manufacturing & focus on optimized biopreservation media. Cell Gene Ther. Ins. 2017; 3(5): 345–58. Hawkins BJ, Abazari A, Mathew AJ. Biopreservation Best Practices for regenerative medicine GMP manufacturing & focus on optimized biopreservation media. Cell Gene Ther. Ins. 2017; 3(5): 345–58. Hawkins BJ, Abazari A, Mathew AJ. Biopreservation Best Practices for regenerative medicine GMP manufacturing & focus on optimized biopreservation media. Cell Gene Ther. Ins. 2017; 3(5): 345–58. Hawkins BJ, Abazari A, Mathew AJ. Biopreservation Best Practices for regenerative medicine GMP manufacturing & focus on optimized biopreservation media. Cell Gene Ther. Ins. 2017; 3(5): 345–58. Hawkins BJ, Abazari A, Mathew AJ. Biopreservation Best Practices for regenerative medicine GMP manufacturing & focus on optimized biopreservation media. Cell Gene Ther. Ins. 2017; 3(5): 345–58. Hawkins BJ, Abazari A, Mathew AJ. Biopreservation Best Practices for regenerative medicine GMP manufacturing & focus on optimized biopreservation media. Cell Gene Ther. Ins. 2017; 3(5): 345–58. Hawkins BJ, Abazari A, Mathew AJ. Biopreservation Best Practices for regenerative medicine GMP manufacturing & focus on optimized biopreservation media. Cell Gene Ther. Ins. 2017; 3(5): 345–58. Hawkins BJ, Abazari A, Mathew AJ. Biopreservation Best Practices for regenerative medicine GMP manufacturing & focus on optimized biopreservation media. Cell Gene Ther. Ins. 2017; 3(5): 345–58. Hawkins BJ, Abazari A, Mathew AJ. Biopreservation Best Practices for regenerative medicine GMP manufacturing & focus on optimized biopreservation media. Cell Gene Ther. Ins. 2017; 3(5): 345–58. Hawkins BJ, Abazari A, Mathew AJ. Biopreservation Best Practices for regenerative medicine GMP manufacturing & focus on optimized biopreservation media. Cell Gene Ther. Ins. 2017; 3(5): 345–58. Hawkins BJ, Abazari A, Mathew AJ. Biopreservation Best Practices for regenerative medicine GMP manufacturing & focus on optimized biopreservation media. Cell Gene Ther. Ins. 2017; 3(5): 345–58. Hawkins BJ, Abazari A, Mathew AJ. Biopreservation Best Practices for regenerative medicine GMP manufacturing & focus on optimized biopreservation media. Cell Gene Ther. Ins. 2017; 3(5): 345–58. Hawkins BJ, Abazari A, Mathew AJ. Biopreservation Best Practices for regenerative medicine GMP manufacturing & focus on optimized biopreservation media. Cell Gene Ther. Ins. 2017; 3(5): 345–58. Hawkins BJ, Abazari A, Mathew AJ. Biopreservation Best Practices for regenerative medicine GMP manufacturing & focus on optimized biopreservation media. Cell Gene Ther. Ins. 2017; 3(5): 345–58. Hawkins BJ, Abazari A, Mathew AJ. Biopreservation Best Practices for regenerative medicine GMP manufacturing & focus on optimized biopreservation media. Cell Gene Ther. Ins. 2017; 3(5): 345–58. ); and

- Exploring and implementing enabling tools and technologies throughout the workflow.

Such tools might consist of: novel CGT processing and packaging technologies; next generation closed systems for fill, finish, and packaging; class-defining biopreservation media; high capacity-controlled rate freezers; cryogenic storage systems; ‘smart’ cold chain management systems (shipping containers, tracking, and reporting); and automated, water-free thawing equipment technologies. [The normothermic culture state of the cells is also a variable that can impact the quality of the cell product, however that is not a focus of this overview.]

Ensuring high quality starting material

The importance of obtaining high quality starting material has been previously highlighted [4]Juliano L, Eastwood G, Berard T, Mathew AJ. The Importance of Collection, Processing and Biopreservation Best Practices in Determining CAR-T Starting Material Quality. Cell Gene Ther. Ins. 2018; 4(4): 327–36.Juliano L, Eastwood G, Berard T, Mathew AJ. The Importance of Collection, Processing and Biopreservation Best Practices in Determining CAR-T Starting Material Quality. Cell Gene Ther. Ins. 2018; 4(4): 327–36.Juliano L, Eastwood G, Berard T, Mathew AJ. The Importance of Collection, Processing and Biopreservation Best Practices in Determining CAR-T Starting Material Quality. Cell Gene Ther. Ins. 2018; 4(4): 327–36.Juliano L, Eastwood G, Berard T, Mathew AJ. The Importance of Collection, Processing and Biopreservation Best Practices in Determining CAR-T Starting Material Quality. Cell Gene Ther. Ins. 2018; 4(4): 327–36., [5]Hawkins BJ, Abazari A, Mathew AJ. Biopreservation Best Practices for regenerative medicine GMP manufacturing & focus on optimized biopreservation media. Cell Gene Ther. Ins. 2017; 3(5): 345–58. Hawkins BJ, Abazari A, Mathew AJ. Biopreservation Best Practices for regenerative medicine GMP manufacturing & focus on optimized biopreservation media. Cell Gene Ther. Ins. 2017; 3(5): 345–58. Hawkins BJ, Abazari A, Mathew AJ. Biopreservation Best Practices for regenerative medicine GMP manufacturing & focus on optimized biopreservation media. Cell Gene Ther. Ins. 2017; 3(5): 345–58. Hawkins BJ, Abazari A, Mathew AJ. Biopreservation Best Practices for regenerative medicine GMP manufacturing & focus on optimized biopreservation media. Cell Gene Ther. Ins. 2017; 3(5): 345–58. Hawkins BJ, Abazari A, Mathew AJ. Biopreservation Best Practices for regenerative medicine GMP manufacturing & focus on optimized biopreservation media. Cell Gene Ther. Ins. 2017; 3(5): 345–58. Hawkins BJ, Abazari A, Mathew AJ. Biopreservation Best Practices for regenerative medicine GMP manufacturing & focus on optimized biopreservation media. Cell Gene Ther. Ins. 2017; 3(5): 345–58. Hawkins BJ, Abazari A, Mathew AJ. Biopreservation Best Practices for regenerative medicine GMP manufacturing & focus on optimized biopreservation media. Cell Gene Ther. Ins. 2017; 3(5): 345–58. Hawkins BJ, Abazari A, Mathew AJ. Biopreservation Best Practices for regenerative medicine GMP manufacturing & focus on optimized biopreservation media. Cell Gene Ther. Ins. 2017; 3(5): 345–58. Hawkins BJ, Abazari A, Mathew AJ. Biopreservation Best Practices for regenerative medicine GMP manufacturing & focus on optimized biopreservation media. Cell Gene Ther. Ins. 2017; 3(5): 345–58. Hawkins BJ, Abazari A, Mathew AJ. Biopreservation Best Practices for regenerative medicine GMP manufacturing & focus on optimized biopreservation media. Cell Gene Ther. Ins. 2017; 3(5): 345–58. Hawkins BJ, Abazari A, Mathew AJ. Biopreservation Best Practices for regenerative medicine GMP manufacturing & focus on optimized biopreservation media. Cell Gene Ther. Ins. 2017; 3(5): 345–58. Hawkins BJ, Abazari A, Mathew AJ. Biopreservation Best Practices for regenerative medicine GMP manufacturing & focus on optimized biopreservation media. Cell Gene Ther. Ins. 2017; 3(5): 345–58. Hawkins BJ, Abazari A, Mathew AJ. Biopreservation Best Practices for regenerative medicine GMP manufacturing & focus on optimized biopreservation media. Cell Gene Ther. Ins. 2017; 3(5): 345–58. Hawkins BJ, Abazari A, Mathew AJ. Biopreservation Best Practices for regenerative medicine GMP manufacturing & focus on optimized biopreservation media. Cell Gene Ther. Ins. 2017; 3(5): 345–58. Hawkins BJ, Abazari A, Mathew AJ. Biopreservation Best Practices for regenerative medicine GMP manufacturing & focus on optimized biopreservation media. Cell Gene Ther. Ins. 2017; 3(5): 345–58. Hawkins BJ, Abazari A, Mathew AJ. Biopreservation Best Practices for regenerative medicine GMP manufacturing & focus on optimized biopreservation media. Cell Gene Ther. Ins. 2017; 3(5): 345–58. , [7]Clarke D, Smith D. Managing starting material stability to maximize manufacturing flexibility and downstream efficiency. Cell Gene Ther. Ins. 2019; 5(2): 303–14.Clarke D, Smith D. Managing starting material stability to maximize manufacturing flexibility and downstream efficiency. Cell Gene Ther. Ins. 2019; 5(2): 303–14.Clarke D, Smith D. Managing starting material stability to maximize manufacturing flexibility and downstream efficiency. Cell Gene Ther. Ins. 2019; 5(2): 303–14.Clarke D, Smith D. Managing starting material stability to maximize manufacturing flexibility and downstream efficiency. Cell Gene Ther. Ins. 2019; 5(2): 303–14.. An early challenge in the CGT manufacturing workflow is ensuring high quality, and consistent, starting material. Cell-based manufacturing and therapies present a unique challenge that does not exist to the same complexity or criticality as with non-cell-based therapies – that difference being the needs, the vulnerabilities, and variability of, living cells. Cells embody an intrinsic variability of normal conditions, response, and function, that can influence the therapeutic efficacy. As such, CGT manufacturing should take into account the inherent variability of starting cell-based materials, as well as the processing methods for these living cells, that will eventually impact the quality of the therapeutic product.

The potential variability and quality of CGT starting materials have been an increasing focus of CGT concern, and has been discussion points of Cell & Gene Therapy Insights experts [4]Juliano L, Eastwood G, Berard T, Mathew AJ. The Importance of Collection, Processing and Biopreservation Best Practices in Determining CAR-T Starting Material Quality. Cell Gene Ther. Ins. 2018; 4(4): 327–36.Juliano L, Eastwood G, Berard T, Mathew AJ. The Importance of Collection, Processing and Biopreservation Best Practices in Determining CAR-T Starting Material Quality. Cell Gene Ther. Ins. 2018; 4(4): 327–36.Juliano L, Eastwood G, Berard T, Mathew AJ. The Importance of Collection, Processing and Biopreservation Best Practices in Determining CAR-T Starting Material Quality. Cell Gene Ther. Ins. 2018; 4(4): 327–36.Juliano L, Eastwood G, Berard T, Mathew AJ. The Importance of Collection, Processing and Biopreservation Best Practices in Determining CAR-T Starting Material Quality. Cell Gene Ther. Ins. 2018; 4(4): 327–36., [7]Clarke D, Smith D. Managing starting material stability to maximize manufacturing flexibility and downstream efficiency. Cell Gene Ther. Ins. 2019; 5(2): 303–14.Clarke D, Smith D. Managing starting material stability to maximize manufacturing flexibility and downstream efficiency. Cell Gene Ther. Ins. 2019; 5(2): 303–14.Clarke D, Smith D. Managing starting material stability to maximize manufacturing flexibility and downstream efficiency. Cell Gene Ther. Ins. 2019; 5(2): 303–14.Clarke D, Smith D. Managing starting material stability to maximize manufacturing flexibility and downstream efficiency. Cell Gene Ther. Ins. 2019; 5(2): 303–14.. Those discussions have also presented evidence-based pathways for increasing the non-frozen or frozen stability, and/or minimizing variability, of cell/tissue starting materials [4]Juliano L, Eastwood G, Berard T, Mathew AJ. The Importance of Collection, Processing and Biopreservation Best Practices in Determining CAR-T Starting Material Quality. Cell Gene Ther. Ins. 2018; 4(4): 327–36.Juliano L, Eastwood G, Berard T, Mathew AJ. The Importance of Collection, Processing and Biopreservation Best Practices in Determining CAR-T Starting Material Quality. Cell Gene Ther. Ins. 2018; 4(4): 327–36.Juliano L, Eastwood G, Berard T, Mathew AJ. The Importance of Collection, Processing and Biopreservation Best Practices in Determining CAR-T Starting Material Quality. Cell Gene Ther. Ins. 2018; 4(4): 327–36.Juliano L, Eastwood G, Berard T, Mathew AJ. The Importance of Collection, Processing and Biopreservation Best Practices in Determining CAR-T Starting Material Quality. Cell Gene Ther. Ins. 2018; 4(4): 327–36., [5]Hawkins BJ, Abazari A, Mathew AJ. Biopreservation Best Practices for regenerative medicine GMP manufacturing & focus on optimized biopreservation media. Cell Gene Ther. Ins. 2017; 3(5): 345–58. Hawkins BJ, Abazari A, Mathew AJ. Biopreservation Best Practices for regenerative medicine GMP manufacturing & focus on optimized biopreservation media. Cell Gene Ther. Ins. 2017; 3(5): 345–58. Hawkins BJ, Abazari A, Mathew AJ. Biopreservation Best Practices for regenerative medicine GMP manufacturing & focus on optimized biopreservation media. Cell Gene Ther. Ins. 2017; 3(5): 345–58. Hawkins BJ, Abazari A, Mathew AJ. Biopreservation Best Practices for regenerative medicine GMP manufacturing & focus on optimized biopreservation media. Cell Gene Ther. Ins. 2017; 3(5): 345–58. Hawkins BJ, Abazari A, Mathew AJ. Biopreservation Best Practices for regenerative medicine GMP manufacturing & focus on optimized biopreservation media. Cell Gene Ther. Ins. 2017; 3(5): 345–58. Hawkins BJ, Abazari A, Mathew AJ. Biopreservation Best Practices for regenerative medicine GMP manufacturing & focus on optimized biopreservation media. Cell Gene Ther. Ins. 2017; 3(5): 345–58. Hawkins BJ, Abazari A, Mathew AJ. Biopreservation Best Practices for regenerative medicine GMP manufacturing & focus on optimized biopreservation media. Cell Gene Ther. Ins. 2017; 3(5): 345–58. Hawkins BJ, Abazari A, Mathew AJ. Biopreservation Best Practices for regenerative medicine GMP manufacturing & focus on optimized biopreservation media. Cell Gene Ther. Ins. 2017; 3(5): 345–58. Hawkins BJ, Abazari A, Mathew AJ. Biopreservation Best Practices for regenerative medicine GMP manufacturing & focus on optimized biopreservation media. Cell Gene Ther. Ins. 2017; 3(5): 345–58. Hawkins BJ, Abazari A, Mathew AJ. Biopreservation Best Practices for regenerative medicine GMP manufacturing & focus on optimized biopreservation media. Cell Gene Ther. Ins. 2017; 3(5): 345–58. Hawkins BJ, Abazari A, Mathew AJ. Biopreservation Best Practices for regenerative medicine GMP manufacturing & focus on optimized biopreservation media. Cell Gene Ther. Ins. 2017; 3(5): 345–58. Hawkins BJ, Abazari A, Mathew AJ. Biopreservation Best Practices for regenerative medicine GMP manufacturing & focus on optimized biopreservation media. Cell Gene Ther. Ins. 2017; 3(5): 345–58. Hawkins BJ, Abazari A, Mathew AJ. Biopreservation Best Practices for regenerative medicine GMP manufacturing & focus on optimized biopreservation media. Cell Gene Ther. Ins. 2017; 3(5): 345–58. Hawkins BJ, Abazari A, Mathew AJ. Biopreservation Best Practices for regenerative medicine GMP manufacturing & focus on optimized biopreservation media. Cell Gene Ther. Ins. 2017; 3(5): 345–58. Hawkins BJ, Abazari A, Mathew AJ. Biopreservation Best Practices for regenerative medicine GMP manufacturing & focus on optimized biopreservation media. Cell Gene Ther. Ins. 2017; 3(5): 345–58. Hawkins BJ, Abazari A, Mathew AJ. Biopreservation Best Practices for regenerative medicine GMP manufacturing & focus on optimized biopreservation media. Cell Gene Ther. Ins. 2017; 3(5): 345–58. , [6]Abazari A, Hawkins BJ, Clarke DM, Mathew AJ. Biopreservation Best Practices: A Cornerstone in the Supply Chain of Cell-based Therapies – MSC Model Case Study. Cell Gene Ther. Ins. 2017; 3(10): 853–71. Abazari A, Hawkins BJ, Clarke DM, Mathew AJ. Biopreservation Best Practices: A Cornerstone in the Supply Chain of Cell-based Therapies – MSC Model Case Study. Cell Gene Ther. Ins. 2017; 3(10): 853–71. Abazari A, Hawkins BJ, Clarke DM, Mathew AJ. Biopreservation Best Practices: A Cornerstone in the Supply Chain of Cell-based Therapies – MSC Model Case Study. Cell Gene Ther. Ins. 2017; 3(10): 853–71. , [7]Clarke D, Smith D. Managing starting material stability to maximize manufacturing flexibility and downstream efficiency. Cell Gene Ther. Ins. 2019; 5(2): 303–14.Clarke D, Smith D. Managing starting material stability to maximize manufacturing flexibility and downstream efficiency. Cell Gene Ther. Ins. 2019; 5(2): 303–14.Clarke D, Smith D. Managing starting material stability to maximize manufacturing flexibility and downstream efficiency. Cell Gene Ther. Ins. 2019; 5(2): 303–14.Clarke D, Smith D. Managing starting material stability to maximize manufacturing flexibility and downstream efficiency. Cell Gene Ther. Ins. 2019; 5(2): 303–14., [8]Abazari A. Process development considerations for cryopreservation of cellular therapies. Cell Gene Ther. Ins. 2019; 5(9): 1151–67.Abazari A. Process development considerations for cryopreservation of cellular therapies. Cell Gene Ther. Ins. 2019; 5(9): 1151–67.Abazari A. Process development considerations for cryopreservation of cellular therapies. Cell Gene Ther. Ins. 2019; 5(9): 1151–67.Abazari A. Process development considerations for cryopreservation of cellular therapies. Cell Gene Ther. Ins. 2019; 5(9): 1151–67.Abazari A. Process development considerations for cryopreservation of cellular therapies. Cell Gene Ther. Ins. 2019; 5(9): 1151–67.Abazari A. Process development considerations for cryopreservation of cellular therapies. Cell Gene Ther. Ins. 2019; 5(9): 1151–67.Abazari A. Process development considerations for cryopreservation of cellular therapies. Cell Gene Ther. Ins. 2019; 5(9): 1151–67.Abazari A. Process development considerations for cryopreservation of cellular therapies. Cell Gene Ther. Ins. 2019; 5(9): 1151–67.Abazari A. Process development considerations for cryopreservation of cellular therapies. Cell Gene Ther. Ins. 2019; 5(9): 1151–67., [9]Abazari A. Implementation of Biopreservation Best Practices to address a critical component of cell and gene therapy manufacturing: https://insights.bio/cell-and-gene-therapy-insights/implementation-of-biopreservation-best-practices-to-address-a-critical-component-of-cell-and-gene-therapy-manufacturing Abazari A. Implementation of Biopreservation Best Practices to address a critical component of cell and gene therapy manufacturing: https://insights.bio/cell-and-gene-therapy-insights/implementation-of-biopreservation-best-practices-to-address-a-critical-component-of-cell-and-gene-therapy-manufacturing Abazari A. Implementation of Biopreservation Best Practices to address a critical component of cell and gene therapy manufacturing: https://insights.bio/cell-and-gene-therapy-insights/implementation-of-biopreservation-best-practices-to-address-a-critical-component-of-cell-and-gene-therapy-manufacturing Abazari A. Implementation of Biopreservation Best Practices to address a critical component of cell and gene therapy manufacturing: https://insights.bio/cell-and-gene-therapy-insights/implementation-of-biopreservation-best-practices-to-address-a-critical-component-of-cell-and-gene-therapy-manufacturing Abazari A. Implementation of Biopreservation Best Practices to address a critical component of cell and gene therapy manufacturing: https://insights.bio/cell-and-gene-therapy-insights/implementation-of-biopreservation-best-practices-to-address-a-critical-component-of-cell-and-gene-therapy-manufacturing Abazari A. Implementation of Biopreservation Best Practices to address a critical component of cell and gene therapy manufacturing: https://insights.bio/cell-and-gene-therapy-insights/implementation-of-biopreservation-best-practices-to-address-a-critical-component-of-cell-and-gene-therapy-manufacturing Abazari A. Implementation of Biopreservation Best Practices to address a critical component of cell and gene therapy manufacturing: https://insights.bio/cell-and-gene-therapy-insights/implementation-of-biopreservation-best-practices-to-address-a-critical-component-of-cell-and-gene-therapy-manufacturing Abazari A. Implementation of Biopreservation Best Practices to address a critical component of cell and gene therapy manufacturing: https://insights.bio/cell-and-gene-therapy-insights/implementation-of-biopreservation-best-practices-to-address-a-critical-component-of-cell-and-gene-therapy-manufacturing Abazari A. Implementation of Biopreservation Best Practices to address a critical component of cell and gene therapy manufacturing: https://insights.bio/cell-and-gene-therapy-insights/implementation-of-biopreservation-best-practices-to-address-a-critical-component-of-cell-and-gene-therapy-manufacturing Abazari A. Implementation of Biopreservation Best Practices to address a critical component of cell and gene therapy manufacturing: https://insights.bio/cell-and-gene-therapy-insights/implementation-of-biopreservation-best-practices-to-address-a-critical-component-of-cell-and-gene-therapy-manufacturing Abazari A. Implementation of Biopreservation Best Practices to address a critical component of cell and gene therapy manufacturing: https://insights.bio/cell-and-gene-therapy-insights/implementation-of-biopreservation-best-practices-to-address-a-critical-component-of-cell-and-gene-therapy-manufacturing .

Non-frozen or frozen? Cellular responses to cold

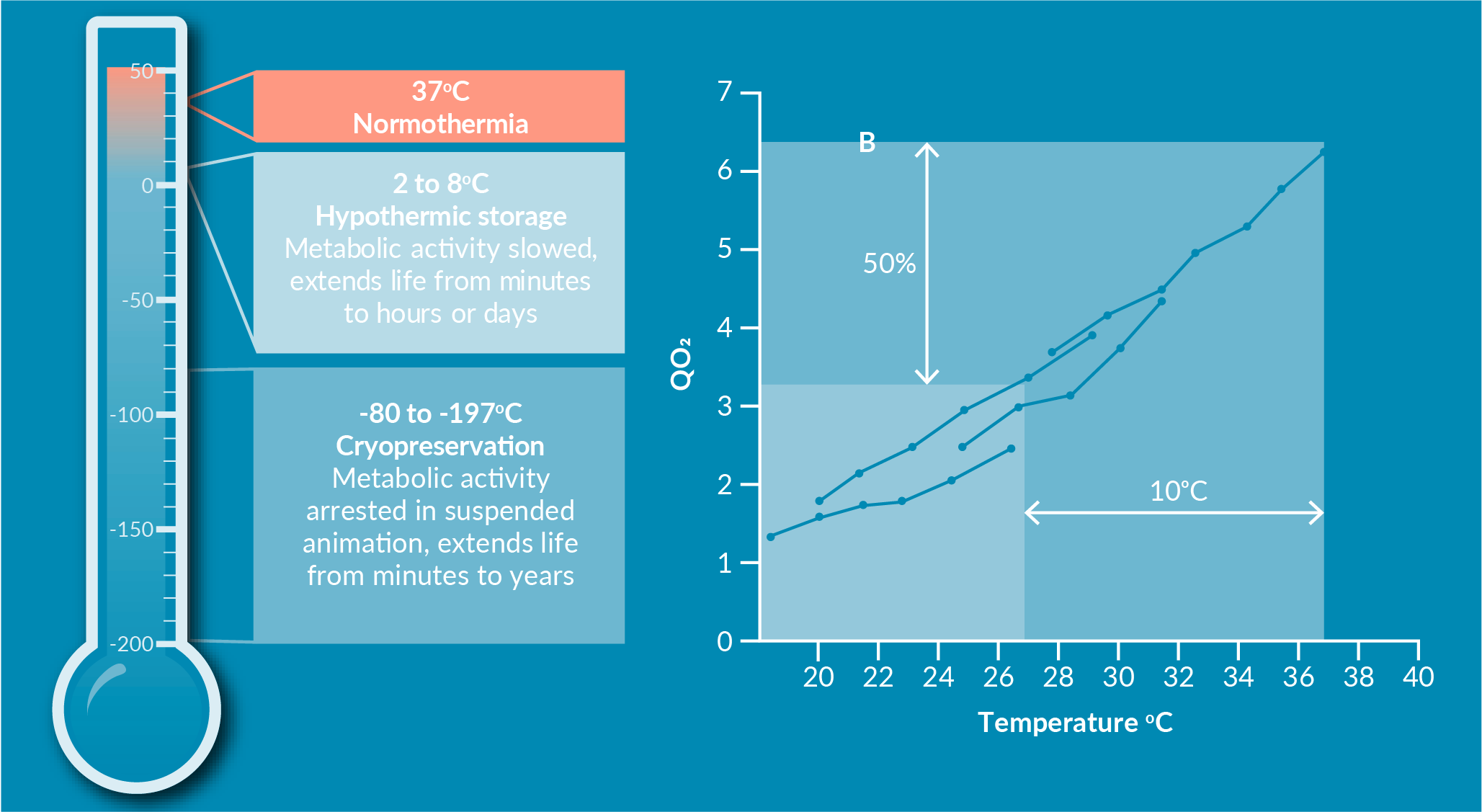

It is important to ask a basic question: How can cell viable recovery and function be preserved throughout the manufacturing workflow, in order to facilitate efficacy? It is recognized that low temperatures can slow metabolic activity, reduce oxygen demand, and decrease degradation; but it may be beneficial to understand the benefits and limitations, in order to support biopreservation optimization and risk management of the process/product.

Figure 2

As temperatures decrease to hypothermic temperatures (below 37°C normothermic), lipid membranes undergo phase transitions: a type of structural change that results in loss of fluidity and continuity. Hypothermia induces phase transitions in the lipid membrane that lead to pore formation and loss of integrity. This leads to an influx and outflux of ions and small molecules due to the cross-membrane concentration gradients [9]Abazari A. Implementation of Biopreservation Best Practices to address a critical component of cell and gene therapy manufacturing: https://insights.bio/cell-and-gene-therapy-insights/implementation-of-biopreservation-best-practices-to-address-a-critical-component-of-cell-and-gene-therapy-manufacturing Abazari A. Implementation of Biopreservation Best Practices to address a critical component of cell and gene therapy manufacturing: https://insights.bio/cell-and-gene-therapy-insights/implementation-of-biopreservation-best-practices-to-address-a-critical-component-of-cell-and-gene-therapy-manufacturing Abazari A. Implementation of Biopreservation Best Practices to address a critical component of cell and gene therapy manufacturing: https://insights.bio/cell-and-gene-therapy-insights/implementation-of-biopreservation-best-practices-to-address-a-critical-component-of-cell-and-gene-therapy-manufacturing Abazari A. Implementation of Biopreservation Best Practices to address a critical component of cell and gene therapy manufacturing: https://insights.bio/cell-and-gene-therapy-insights/implementation-of-biopreservation-best-practices-to-address-a-critical-component-of-cell-and-gene-therapy-manufacturing Abazari A. Implementation of Biopreservation Best Practices to address a critical component of cell and gene therapy manufacturing: https://insights.bio/cell-and-gene-therapy-insights/implementation-of-biopreservation-best-practices-to-address-a-critical-component-of-cell-and-gene-therapy-manufacturing Abazari A. Implementation of Biopreservation Best Practices to address a critical component of cell and gene therapy manufacturing: https://insights.bio/cell-and-gene-therapy-insights/implementation-of-biopreservation-best-practices-to-address-a-critical-component-of-cell-and-gene-therapy-manufacturing Abazari A. Implementation of Biopreservation Best Practices to address a critical component of cell and gene therapy manufacturing: https://insights.bio/cell-and-gene-therapy-insights/implementation-of-biopreservation-best-practices-to-address-a-critical-component-of-cell-and-gene-therapy-manufacturing Abazari A. Implementation of Biopreservation Best Practices to address a critical component of cell and gene therapy manufacturing: https://insights.bio/cell-and-gene-therapy-insights/implementation-of-biopreservation-best-practices-to-address-a-critical-component-of-cell-and-gene-therapy-manufacturing Abazari A. Implementation of Biopreservation Best Practices to address a critical component of cell and gene therapy manufacturing: https://insights.bio/cell-and-gene-therapy-insights/implementation-of-biopreservation-best-practices-to-address-a-critical-component-of-cell-and-gene-therapy-manufacturing Abazari A. Implementation of Biopreservation Best Practices to address a critical component of cell and gene therapy manufacturing: https://insights.bio/cell-and-gene-therapy-insights/implementation-of-biopreservation-best-practices-to-address-a-critical-component-of-cell-and-gene-therapy-manufacturing Abazari A. Implementation of Biopreservation Best Practices to address a critical component of cell and gene therapy manufacturing: https://insights.bio/cell-and-gene-therapy-insights/implementation-of-biopreservation-best-practices-to-address-a-critical-component-of-cell-and-gene-therapy-manufacturing . Under hypothermic conditions, there is deceleration of ion pumps and reduced ATP synthesis by mitochondria. Ion pumps then have a reduced capacity to regulate intracellular ions, leading to a myriad of issues. This further impedes restoration of ionic balance in the intracellular milieu. This disrupts the overall ionic balance, resulting in dysfunctions in intracellular cell signaling, salinity, osmolality pathways, osmosis, and cell volume, that previously relied on a tightly regulated cell balance. Osmolality and ionic distortions can induce mitochondrial stresses, which can initiate a cascade of adverse events within the cell by increased reactive oxygen species (ROS) and free radicals generation, and lipid peroxidation. When combined with membrane phase transitions, these phenomena can lead to membrane blebbing and other irreversible membrane injuries, among other mechanisms of cell damage and cell death [5]Hawkins BJ, Abazari A, Mathew AJ. Biopreservation Best Practices for regenerative medicine GMP manufacturing & focus on optimized biopreservation media. Cell Gene Ther. Ins. 2017; 3(5): 345–58. Hawkins BJ, Abazari A, Mathew AJ. Biopreservation Best Practices for regenerative medicine GMP manufacturing & focus on optimized biopreservation media. Cell Gene Ther. Ins. 2017; 3(5): 345–58. Hawkins BJ, Abazari A, Mathew AJ. Biopreservation Best Practices for regenerative medicine GMP manufacturing & focus on optimized biopreservation media. Cell Gene Ther. Ins. 2017; 3(5): 345–58. Hawkins BJ, Abazari A, Mathew AJ. Biopreservation Best Practices for regenerative medicine GMP manufacturing & focus on optimized biopreservation media. Cell Gene Ther. Ins. 2017; 3(5): 345–58. Hawkins BJ, Abazari A, Mathew AJ. Biopreservation Best Practices for regenerative medicine GMP manufacturing & focus on optimized biopreservation media. Cell Gene Ther. Ins. 2017; 3(5): 345–58. Hawkins BJ, Abazari A, Mathew AJ. Biopreservation Best Practices for regenerative medicine GMP manufacturing & focus on optimized biopreservation media. Cell Gene Ther. Ins. 2017; 3(5): 345–58. Hawkins BJ, Abazari A, Mathew AJ. Biopreservation Best Practices for regenerative medicine GMP manufacturing & focus on optimized biopreservation media. Cell Gene Ther. Ins. 2017; 3(5): 345–58. Hawkins BJ, Abazari A, Mathew AJ. Biopreservation Best Practices for regenerative medicine GMP manufacturing & focus on optimized biopreservation media. Cell Gene Ther. Ins. 2017; 3(5): 345–58. Hawkins BJ, Abazari A, Mathew AJ. Biopreservation Best Practices for regenerative medicine GMP manufacturing & focus on optimized biopreservation media. Cell Gene Ther. Ins. 2017; 3(5): 345–58. Hawkins BJ, Abazari A, Mathew AJ. Biopreservation Best Practices for regenerative medicine GMP manufacturing & focus on optimized biopreservation media. Cell Gene Ther. Ins. 2017; 3(5): 345–58. Hawkins BJ, Abazari A, Mathew AJ. Biopreservation Best Practices for regenerative medicine GMP manufacturing & focus on optimized biopreservation media. Cell Gene Ther. Ins. 2017; 3(5): 345–58. Hawkins BJ, Abazari A, Mathew AJ. Biopreservation Best Practices for regenerative medicine GMP manufacturing & focus on optimized biopreservation media. Cell Gene Ther. Ins. 2017; 3(5): 345–58. Hawkins BJ, Abazari A, Mathew AJ. Biopreservation Best Practices for regenerative medicine GMP manufacturing & focus on optimized biopreservation media. Cell Gene Ther. Ins. 2017; 3(5): 345–58. Hawkins BJ, Abazari A, Mathew AJ. Biopreservation Best Practices for regenerative medicine GMP manufacturing & focus on optimized biopreservation media. Cell Gene Ther. Ins. 2017; 3(5): 345–58. Hawkins BJ, Abazari A, Mathew AJ. Biopreservation Best Practices for regenerative medicine GMP manufacturing & focus on optimized biopreservation media. Cell Gene Ther. Ins. 2017; 3(5): 345–58. Hawkins BJ, Abazari A, Mathew AJ. Biopreservation Best Practices for regenerative medicine GMP manufacturing & focus on optimized biopreservation media. Cell Gene Ther. Ins. 2017; 3(5): 345–58. , [9]Abazari A. Implementation of Biopreservation Best Practices to address a critical component of cell and gene therapy manufacturing: https://insights.bio/cell-and-gene-therapy-insights/implementation-of-biopreservation-best-practices-to-address-a-critical-component-of-cell-and-gene-therapy-manufacturing Abazari A. Implementation of Biopreservation Best Practices to address a critical component of cell and gene therapy manufacturing: https://insights.bio/cell-and-gene-therapy-insights/implementation-of-biopreservation-best-practices-to-address-a-critical-component-of-cell-and-gene-therapy-manufacturing Abazari A. Implementation of Biopreservation Best Practices to address a critical component of cell and gene therapy manufacturing: https://insights.bio/cell-and-gene-therapy-insights/implementation-of-biopreservation-best-practices-to-address-a-critical-component-of-cell-and-gene-therapy-manufacturing Abazari A. Implementation of Biopreservation Best Practices to address a critical component of cell and gene therapy manufacturing: https://insights.bio/cell-and-gene-therapy-insights/implementation-of-biopreservation-best-practices-to-address-a-critical-component-of-cell-and-gene-therapy-manufacturing Abazari A. Implementation of Biopreservation Best Practices to address a critical component of cell and gene therapy manufacturing: https://insights.bio/cell-and-gene-therapy-insights/implementation-of-biopreservation-best-practices-to-address-a-critical-component-of-cell-and-gene-therapy-manufacturing Abazari A. Implementation of Biopreservation Best Practices to address a critical component of cell and gene therapy manufacturing: https://insights.bio/cell-and-gene-therapy-insights/implementation-of-biopreservation-best-practices-to-address-a-critical-component-of-cell-and-gene-therapy-manufacturing Abazari A. Implementation of Biopreservation Best Practices to address a critical component of cell and gene therapy manufacturing: https://insights.bio/cell-and-gene-therapy-insights/implementation-of-biopreservation-best-practices-to-address-a-critical-component-of-cell-and-gene-therapy-manufacturing Abazari A. Implementation of Biopreservation Best Practices to address a critical component of cell and gene therapy manufacturing: https://insights.bio/cell-and-gene-therapy-insights/implementation-of-biopreservation-best-practices-to-address-a-critical-component-of-cell-and-gene-therapy-manufacturing Abazari A. Implementation of Biopreservation Best Practices to address a critical component of cell and gene therapy manufacturing: https://insights.bio/cell-and-gene-therapy-insights/implementation-of-biopreservation-best-practices-to-address-a-critical-component-of-cell-and-gene-therapy-manufacturing Abazari A. Implementation of Biopreservation Best Practices to address a critical component of cell and gene therapy manufacturing: https://insights.bio/cell-and-gene-therapy-insights/implementation-of-biopreservation-best-practices-to-address-a-critical-component-of-cell-and-gene-therapy-manufacturing Abazari A. Implementation of Biopreservation Best Practices to address a critical component of cell and gene therapy manufacturing: https://insights.bio/cell-and-gene-therapy-insights/implementation-of-biopreservation-best-practices-to-address-a-critical-component-of-cell-and-gene-therapy-manufacturing , [10]Mathew AJ. Biopreservation Considerations for Regenerative Medicine GMP Manufacturing; 2018: http://ebook.liebertpub.com/biolife-solutions/biopreservation-considerations-for-regenerative-medicine-gmp-manufacturing Mathew AJ. Biopreservation Considerations for Regenerative Medicine GMP Manufacturing; 2018: http://ebook.liebertpub.com/biolife-solutions/biopreservation-considerations-for-regenerative-medicine-gmp-manufacturing Mathew AJ. Biopreservation Considerations for Regenerative Medicine GMP Manufacturing; 2018: http://ebook.liebertpub.com/biolife-solutions/biopreservation-considerations-for-regenerative-medicine-gmp-manufacturing Mathew AJ. Biopreservation Considerations for Regenerative Medicine GMP Manufacturing; 2018: http://ebook.liebertpub.com/biolife-solutions/biopreservation-considerations-for-regenerative-medicine-gmp-manufacturing Mathew AJ. Biopreservation Considerations for Regenerative Medicine GMP Manufacturing; 2018: http://ebook.liebertpub.com/biolife-solutions/biopreservation-considerations-for-regenerative-medicine-gmp-manufacturing .

Furthermore, in the absence of oxygen and normothermic conditions, glycolysis becomes the main source of limited ATP generation instead of oxidative phosphorylation, resulting in acidification of the intracellular milieu. Changes in pH and salinity may irreversibly impact protein solubility and its functional structures, which are necessary for protein-protein interactions and trans-membrane positioning.

Temporal accumulation of these damages during hypothermic intervals and storage may eventually overflow beyond the tolerable limits for the cell, leading to irreversible activation of apoptosis, necrosis, and secondary necrosis cascades; at which point, the cell is lost. In addition, the actual onset of cell damage and cell death may not translate until post-preservation and re-warming, and may subsequently manifest as Delayed Onset Cell Death [5]Hawkins BJ, Abazari A, Mathew AJ. Biopreservation Best Practices for regenerative medicine GMP manufacturing & focus on optimized biopreservation media. Cell Gene Ther. Ins. 2017; 3(5): 345–58. Hawkins BJ, Abazari A, Mathew AJ. Biopreservation Best Practices for regenerative medicine GMP manufacturing & focus on optimized biopreservation media. Cell Gene Ther. Ins. 2017; 3(5): 345–58. Hawkins BJ, Abazari A, Mathew AJ. Biopreservation Best Practices for regenerative medicine GMP manufacturing & focus on optimized biopreservation media. Cell Gene Ther. Ins. 2017; 3(5): 345–58. Hawkins BJ, Abazari A, Mathew AJ. Biopreservation Best Practices for regenerative medicine GMP manufacturing & focus on optimized biopreservation media. Cell Gene Ther. Ins. 2017; 3(5): 345–58. Hawkins BJ, Abazari A, Mathew AJ. Biopreservation Best Practices for regenerative medicine GMP manufacturing & focus on optimized biopreservation media. Cell Gene Ther. Ins. 2017; 3(5): 345–58. Hawkins BJ, Abazari A, Mathew AJ. Biopreservation Best Practices for regenerative medicine GMP manufacturing & focus on optimized biopreservation media. Cell Gene Ther. Ins. 2017; 3(5): 345–58. Hawkins BJ, Abazari A, Mathew AJ. Biopreservation Best Practices for regenerative medicine GMP manufacturing & focus on optimized biopreservation media. Cell Gene Ther. Ins. 2017; 3(5): 345–58. Hawkins BJ, Abazari A, Mathew AJ. Biopreservation Best Practices for regenerative medicine GMP manufacturing & focus on optimized biopreservation media. Cell Gene Ther. Ins. 2017; 3(5): 345–58. Hawkins BJ, Abazari A, Mathew AJ. Biopreservation Best Practices for regenerative medicine GMP manufacturing & focus on optimized biopreservation media. Cell Gene Ther. Ins. 2017; 3(5): 345–58. Hawkins BJ, Abazari A, Mathew AJ. Biopreservation Best Practices for regenerative medicine GMP manufacturing & focus on optimized biopreservation media. Cell Gene Ther. Ins. 2017; 3(5): 345–58. Hawkins BJ, Abazari A, Mathew AJ. Biopreservation Best Practices for regenerative medicine GMP manufacturing & focus on optimized biopreservation media. Cell Gene Ther. Ins. 2017; 3(5): 345–58. Hawkins BJ, Abazari A, Mathew AJ. Biopreservation Best Practices for regenerative medicine GMP manufacturing & focus on optimized biopreservation media. Cell Gene Ther. Ins. 2017; 3(5): 345–58. Hawkins BJ, Abazari A, Mathew AJ. Biopreservation Best Practices for regenerative medicine GMP manufacturing & focus on optimized biopreservation media. Cell Gene Ther. Ins. 2017; 3(5): 345–58. Hawkins BJ, Abazari A, Mathew AJ. Biopreservation Best Practices for regenerative medicine GMP manufacturing & focus on optimized biopreservation media. Cell Gene Ther. Ins. 2017; 3(5): 345–58. Hawkins BJ, Abazari A, Mathew AJ. Biopreservation Best Practices for regenerative medicine GMP manufacturing & focus on optimized biopreservation media. Cell Gene Ther. Ins. 2017; 3(5): 345–58. Hawkins BJ, Abazari A, Mathew AJ. Biopreservation Best Practices for regenerative medicine GMP manufacturing & focus on optimized biopreservation media. Cell Gene Ther. Ins. 2017; 3(5): 345–58. , [10]Mathew AJ. Biopreservation Considerations for Regenerative Medicine GMP Manufacturing; 2018: http://ebook.liebertpub.com/biolife-solutions/biopreservation-considerations-for-regenerative-medicine-gmp-manufacturing Mathew AJ. Biopreservation Considerations for Regenerative Medicine GMP Manufacturing; 2018: http://ebook.liebertpub.com/biolife-solutions/biopreservation-considerations-for-regenerative-medicine-gmp-manufacturing Mathew AJ. Biopreservation Considerations for Regenerative Medicine GMP Manufacturing; 2018: http://ebook.liebertpub.com/biolife-solutions/biopreservation-considerations-for-regenerative-medicine-gmp-manufacturing Mathew AJ. Biopreservation Considerations for Regenerative Medicine GMP Manufacturing; 2018: http://ebook.liebertpub.com/biolife-solutions/biopreservation-considerations-for-regenerative-medicine-gmp-manufacturing Mathew AJ. Biopreservation Considerations for Regenerative Medicine GMP Manufacturing; 2018: http://ebook.liebertpub.com/biolife-solutions/biopreservation-considerations-for-regenerative-medicine-gmp-manufacturing .

To alleviate some of these issues, an intracellular-like designed biopreservation media may be incorporated to replace traditional saline/culture media (or other formulations that mimic the normothermic isotonic ionic balance). By reducing the cross-membrane concentration gradient of ions during cold exposure, intracellular ionic balance and salinity would be less altered, even if membrane permeability is impacted. Biopreservation Critical Quality Attributes (BCQA) incorporate intracellular-like design, including impermeant (non-permeating) molecules such as large sugars, which exert membrane-stabilizing and osmotic-supporting effects, in order to mitigate cell swelling and membrane damage during storage. Free radical scavengers can decrease the burden of ROS. Also, buffers that are effective specifically at low temperatures, in contrast to traditional buffers for normothermic conditions, may be more effective at controlling toxic pH changes [5]Hawkins BJ, Abazari A, Mathew AJ. Biopreservation Best Practices for regenerative medicine GMP manufacturing & focus on optimized biopreservation media. Cell Gene Ther. Ins. 2017; 3(5): 345–58. Hawkins BJ, Abazari A, Mathew AJ. Biopreservation Best Practices for regenerative medicine GMP manufacturing & focus on optimized biopreservation media. Cell Gene Ther. Ins. 2017; 3(5): 345–58. Hawkins BJ, Abazari A, Mathew AJ. Biopreservation Best Practices for regenerative medicine GMP manufacturing & focus on optimized biopreservation media. Cell Gene Ther. Ins. 2017; 3(5): 345–58. Hawkins BJ, Abazari A, Mathew AJ. Biopreservation Best Practices for regenerative medicine GMP manufacturing & focus on optimized biopreservation media. Cell Gene Ther. Ins. 2017; 3(5): 345–58. Hawkins BJ, Abazari A, Mathew AJ. Biopreservation Best Practices for regenerative medicine GMP manufacturing & focus on optimized biopreservation media. Cell Gene Ther. Ins. 2017; 3(5): 345–58. Hawkins BJ, Abazari A, Mathew AJ. Biopreservation Best Practices for regenerative medicine GMP manufacturing & focus on optimized biopreservation media. Cell Gene Ther. Ins. 2017; 3(5): 345–58. Hawkins BJ, Abazari A, Mathew AJ. Biopreservation Best Practices for regenerative medicine GMP manufacturing & focus on optimized biopreservation media. Cell Gene Ther. Ins. 2017; 3(5): 345–58. Hawkins BJ, Abazari A, Mathew AJ. Biopreservation Best Practices for regenerative medicine GMP manufacturing & focus on optimized biopreservation media. Cell Gene Ther. Ins. 2017; 3(5): 345–58. Hawkins BJ, Abazari A, Mathew AJ. Biopreservation Best Practices for regenerative medicine GMP manufacturing & focus on optimized biopreservation media. Cell Gene Ther. Ins. 2017; 3(5): 345–58. Hawkins BJ, Abazari A, Mathew AJ. Biopreservation Best Practices for regenerative medicine GMP manufacturing & focus on optimized biopreservation media. Cell Gene Ther. Ins. 2017; 3(5): 345–58. Hawkins BJ, Abazari A, Mathew AJ. Biopreservation Best Practices for regenerative medicine GMP manufacturing & focus on optimized biopreservation media. Cell Gene Ther. Ins. 2017; 3(5): 345–58. Hawkins BJ, Abazari A, Mathew AJ. Biopreservation Best Practices for regenerative medicine GMP manufacturing & focus on optimized biopreservation media. Cell Gene Ther. Ins. 2017; 3(5): 345–58. Hawkins BJ, Abazari A, Mathew AJ. Biopreservation Best Practices for regenerative medicine GMP manufacturing & focus on optimized biopreservation media. Cell Gene Ther. Ins. 2017; 3(5): 345–58. Hawkins BJ, Abazari A, Mathew AJ. Biopreservation Best Practices for regenerative medicine GMP manufacturing & focus on optimized biopreservation media. Cell Gene Ther. Ins. 2017; 3(5): 345–58. Hawkins BJ, Abazari A, Mathew AJ. Biopreservation Best Practices for regenerative medicine GMP manufacturing & focus on optimized biopreservation media. Cell Gene Ther. Ins. 2017; 3(5): 345–58. Hawkins BJ, Abazari A, Mathew AJ. Biopreservation Best Practices for regenerative medicine GMP manufacturing & focus on optimized biopreservation media. Cell Gene Ther. Ins. 2017; 3(5): 345–58. . This intracellular-like approach to Biopreservation Best Practices is applicable to non-frozen hypothermic preservation and cryopreservation.

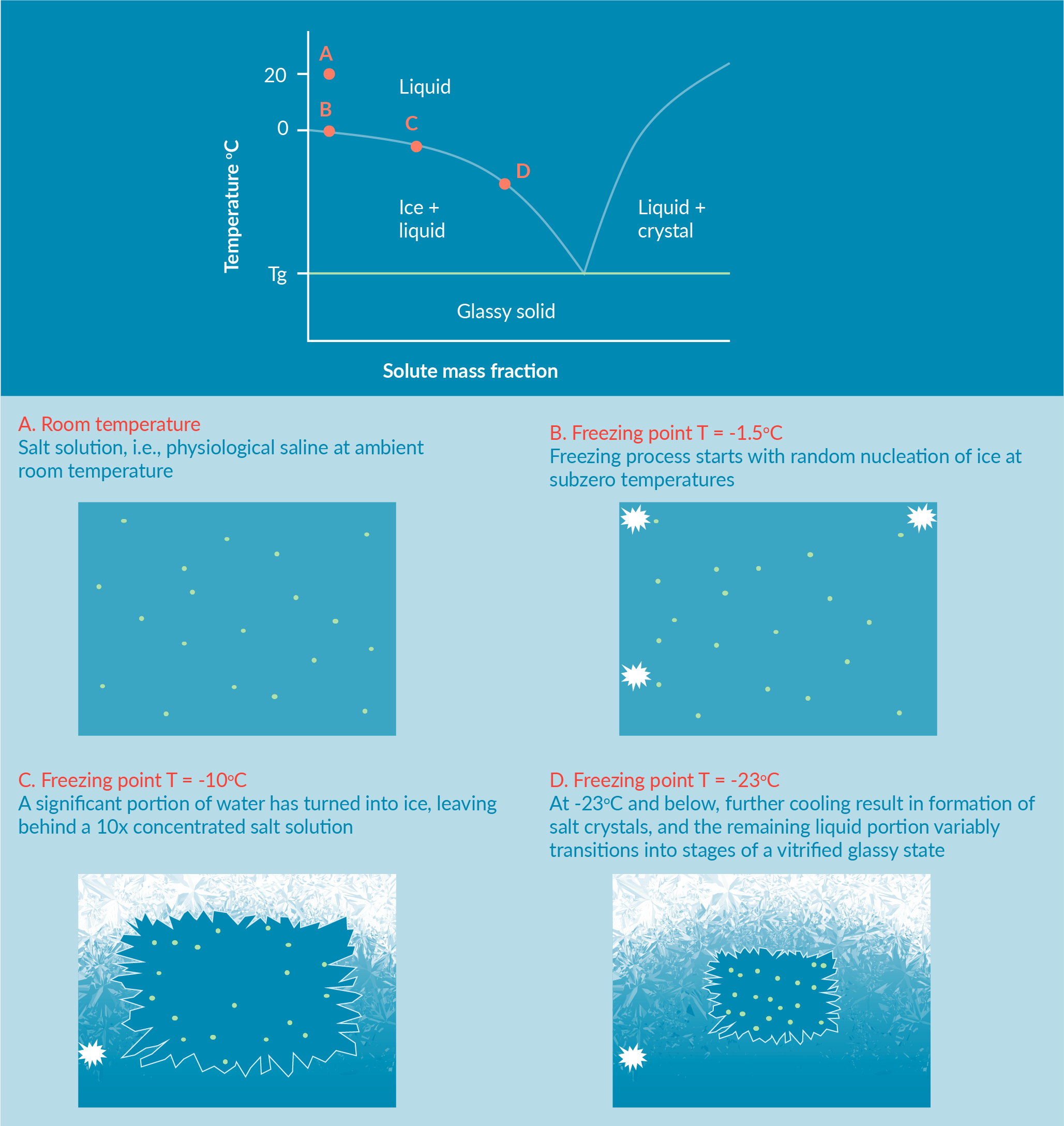

The physics of freezing

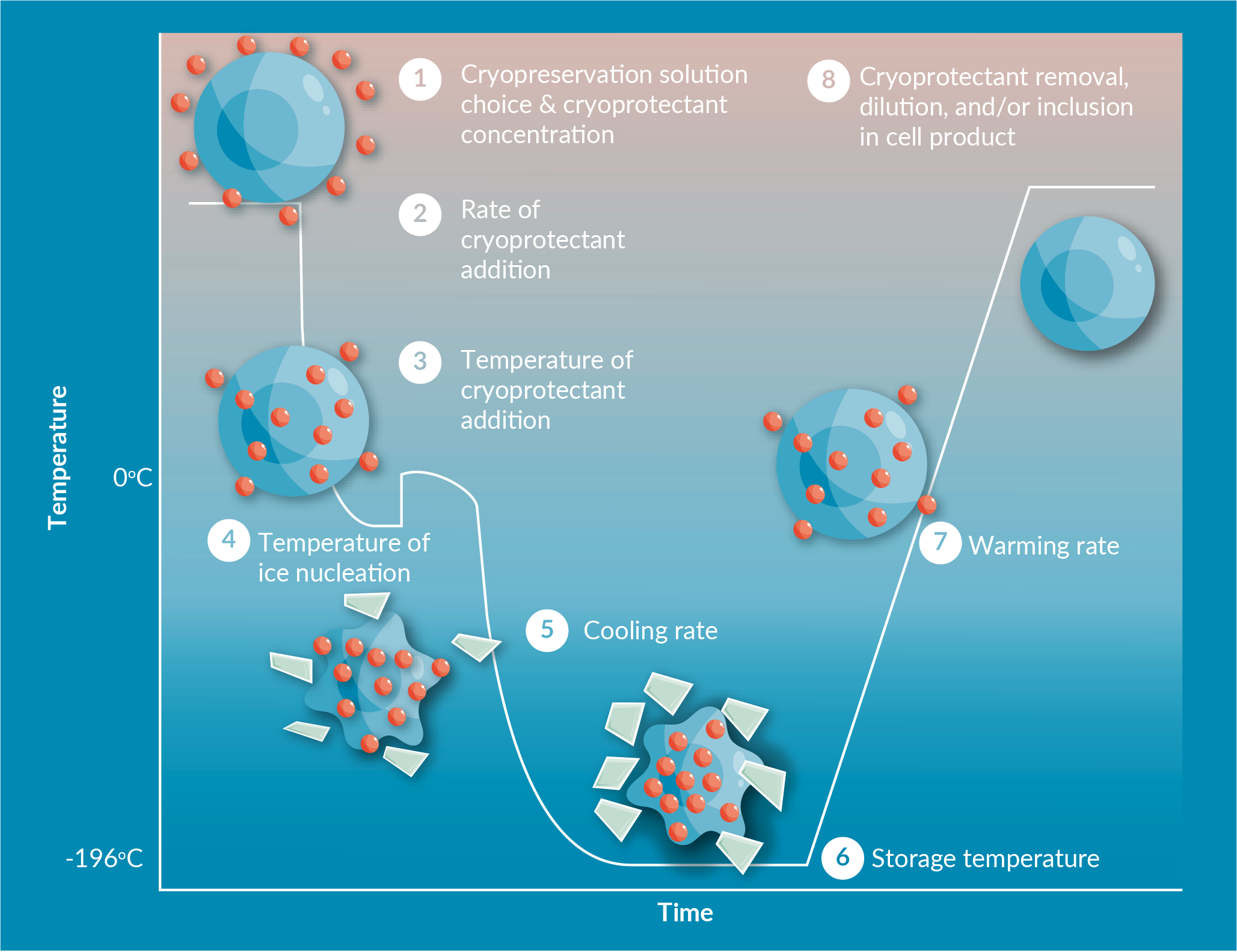

Another mode of cell and tissue biopreservation is cryopreservation. Hypothermia-induced acute stresses occur slowly and accumulate during the storage period. The accumulation of such adverse effects on cells usually trigger cell damage and cell death after hours to days in cold storage. On the other hand, acute cellular stresses during freezing conditions and cryopreservation occur within a relatively short period of freeze-thaw. For both modes of biopreservation, many cell damage and cell death effectors may only fully manifest over 24–72 hours post-preservation via Delayed Onset Cell Death [5]Hawkins BJ, Abazari A, Mathew AJ. Biopreservation Best Practices for regenerative medicine GMP manufacturing & focus on optimized biopreservation media. Cell Gene Ther. Ins. 2017; 3(5): 345–58. Hawkins BJ, Abazari A, Mathew AJ. Biopreservation Best Practices for regenerative medicine GMP manufacturing & focus on optimized biopreservation media. Cell Gene Ther. Ins. 2017; 3(5): 345–58. Hawkins BJ, Abazari A, Mathew AJ. Biopreservation Best Practices for regenerative medicine GMP manufacturing & focus on optimized biopreservation media. Cell Gene Ther. Ins. 2017; 3(5): 345–58. Hawkins BJ, Abazari A, Mathew AJ. Biopreservation Best Practices for regenerative medicine GMP manufacturing & focus on optimized biopreservation media. Cell Gene Ther. Ins. 2017; 3(5): 345–58. Hawkins BJ, Abazari A, Mathew AJ. Biopreservation Best Practices for regenerative medicine GMP manufacturing & focus on optimized biopreservation media. Cell Gene Ther. Ins. 2017; 3(5): 345–58. Hawkins BJ, Abazari A, Mathew AJ. Biopreservation Best Practices for regenerative medicine GMP manufacturing & focus on optimized biopreservation media. Cell Gene Ther. Ins. 2017; 3(5): 345–58. Hawkins BJ, Abazari A, Mathew AJ. Biopreservation Best Practices for regenerative medicine GMP manufacturing & focus on optimized biopreservation media. Cell Gene Ther. Ins. 2017; 3(5): 345–58. Hawkins BJ, Abazari A, Mathew AJ. Biopreservation Best Practices for regenerative medicine GMP manufacturing & focus on optimized biopreservation media. Cell Gene Ther. Ins. 2017; 3(5): 345–58. Hawkins BJ, Abazari A, Mathew AJ. Biopreservation Best Practices for regenerative medicine GMP manufacturing & focus on optimized biopreservation media. Cell Gene Ther. Ins. 2017; 3(5): 345–58. Hawkins BJ, Abazari A, Mathew AJ. Biopreservation Best Practices for regenerative medicine GMP manufacturing & focus on optimized biopreservation media. Cell Gene Ther. Ins. 2017; 3(5): 345–58. Hawkins BJ, Abazari A, Mathew AJ. Biopreservation Best Practices for regenerative medicine GMP manufacturing & focus on optimized biopreservation media. Cell Gene Ther. Ins. 2017; 3(5): 345–58. Hawkins BJ, Abazari A, Mathew AJ. Biopreservation Best Practices for regenerative medicine GMP manufacturing & focus on optimized biopreservation media. Cell Gene Ther. Ins. 2017; 3(5): 345–58. Hawkins BJ, Abazari A, Mathew AJ. Biopreservation Best Practices for regenerative medicine GMP manufacturing & focus on optimized biopreservation media. Cell Gene Ther. Ins. 2017; 3(5): 345–58. Hawkins BJ, Abazari A, Mathew AJ. Biopreservation Best Practices for regenerative medicine GMP manufacturing & focus on optimized biopreservation media. Cell Gene Ther. Ins. 2017; 3(5): 345–58. Hawkins BJ, Abazari A, Mathew AJ. Biopreservation Best Practices for regenerative medicine GMP manufacturing & focus on optimized biopreservation media. Cell Gene Ther. Ins. 2017; 3(5): 345–58. Hawkins BJ, Abazari A, Mathew AJ. Biopreservation Best Practices for regenerative medicine GMP manufacturing & focus on optimized biopreservation media. Cell Gene Ther. Ins. 2017; 3(5): 345–58. , [10]Mathew AJ. Biopreservation Considerations for Regenerative Medicine GMP Manufacturing; 2018: http://ebook.liebertpub.com/biolife-solutions/biopreservation-considerations-for-regenerative-medicine-gmp-manufacturing Mathew AJ. Biopreservation Considerations for Regenerative Medicine GMP Manufacturing; 2018: http://ebook.liebertpub.com/biolife-solutions/biopreservation-considerations-for-regenerative-medicine-gmp-manufacturing Mathew AJ. Biopreservation Considerations for Regenerative Medicine GMP Manufacturing; 2018: http://ebook.liebertpub.com/biolife-solutions/biopreservation-considerations-for-regenerative-medicine-gmp-manufacturing Mathew AJ. Biopreservation Considerations for Regenerative Medicine GMP Manufacturing; 2018: http://ebook.liebertpub.com/biolife-solutions/biopreservation-considerations-for-regenerative-medicine-gmp-manufacturing Mathew AJ. Biopreservation Considerations for Regenerative Medicine GMP Manufacturing; 2018: http://ebook.liebertpub.com/biolife-solutions/biopreservation-considerations-for-regenerative-medicine-gmp-manufacturing . To better understand the physical and chemical stresses during freezing conditions, consider a cell suspension in a simple salt solution such as physiological saline. In Figure 3

The freezing process starts with cooling the solution to below its freezing point (Figure 3A). Once the first ice nuclei form at subzero temperatures, ice crystals grow until they reach an equilibrium with the remaining unfrozen fraction. As ice crystals form from pure water, the unfrozen fraction now contains a higher salt concentration and a lower freezing point. The cells remain in the channels of the unfrozen fraction [11]Mazur P. The role of intracellular freezing in the death of cells cooled at supraoptimal rates. Cryobiology 1977; 14: 251–72. Mazur P. The role of intracellular freezing in the death of cells cooled at supraoptimal rates. Cryobiology 1977; 14: 251–72. Mazur P. The role of intracellular freezing in the death of cells cooled at supraoptimal rates. Cryobiology 1977; 14: 251–72. , [12]Chen HH, Clarke DM, Gao D. Direct concentration measurements of the unfrozen portion of solutions under freezing. Cryobiology 2010; 61: 161–5. .

As freezing continues by reducing the temperature, more water solidifies out of the solution in the form of ice, resulting in increased salinity, solute toxicity, and increasingly lower freezing temperature of the remaining unfrozen fraction (Figure 3B & C).

The cells in the unfrozen fraction are then exposed to increasing salinity (and solute toxicity) as the temperature plunges (Figure 3D). At temperatures in the range below -20°C, the salinity of the unfrozen fraction may be up to 10–20 times the normothermic initial salinity. Recall that cell membranes become more permeable at lower temperatures. This increased salinity, and solute toxicity, impacts the intracellular milieu during freezing. Therefore, the magnitude of freezing-related stresses due to physical effectors (ice formation), and biochemical effectors (salinity, solute toxicity, protein structural damages, intracellular signals, etc.) is not insignificant. Furthermore, the cells respond osmotically to increased extracellular solute concentration by shrinking in size due to water efflux. Cells that are sensitive to these mechanical and biochemical changes are more likely to experience cell injury and cell death during freezing, including as freezing continues toward the glass transition temperature (Tg) of the cell-solution mixture, and then as vitrification into a glassy state occurs, under appropriate conditions [11]Mazur P. The role of intracellular freezing in the death of cells cooled at supraoptimal rates. Cryobiology 1977; 14: 251–72. Mazur P. The role of intracellular freezing in the death of cells cooled at supraoptimal rates. Cryobiology 1977; 14: 251–72. Mazur P. The role of intracellular freezing in the death of cells cooled at supraoptimal rates. Cryobiology 1977; 14: 251–72. .

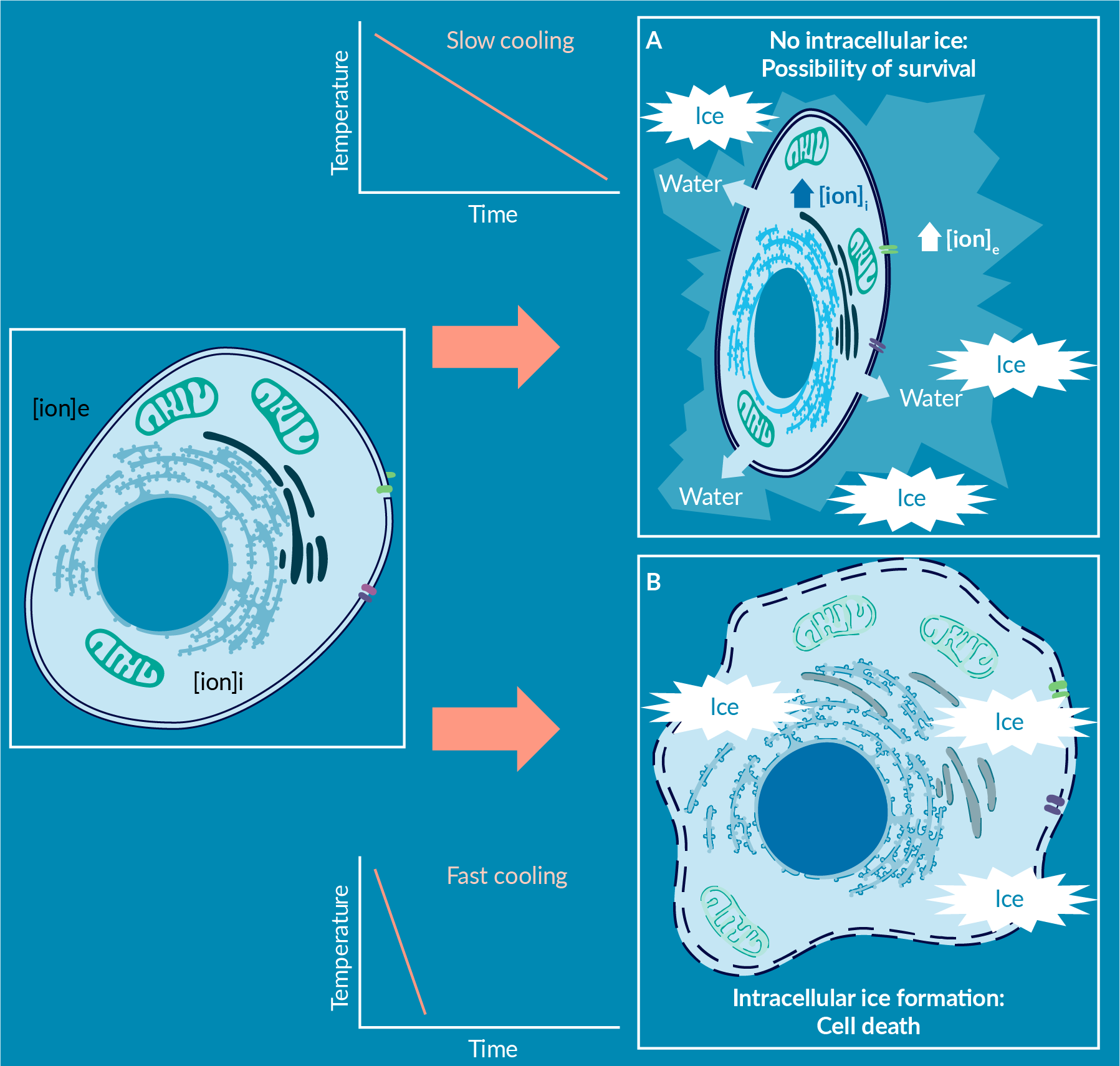

The cell response to freezing

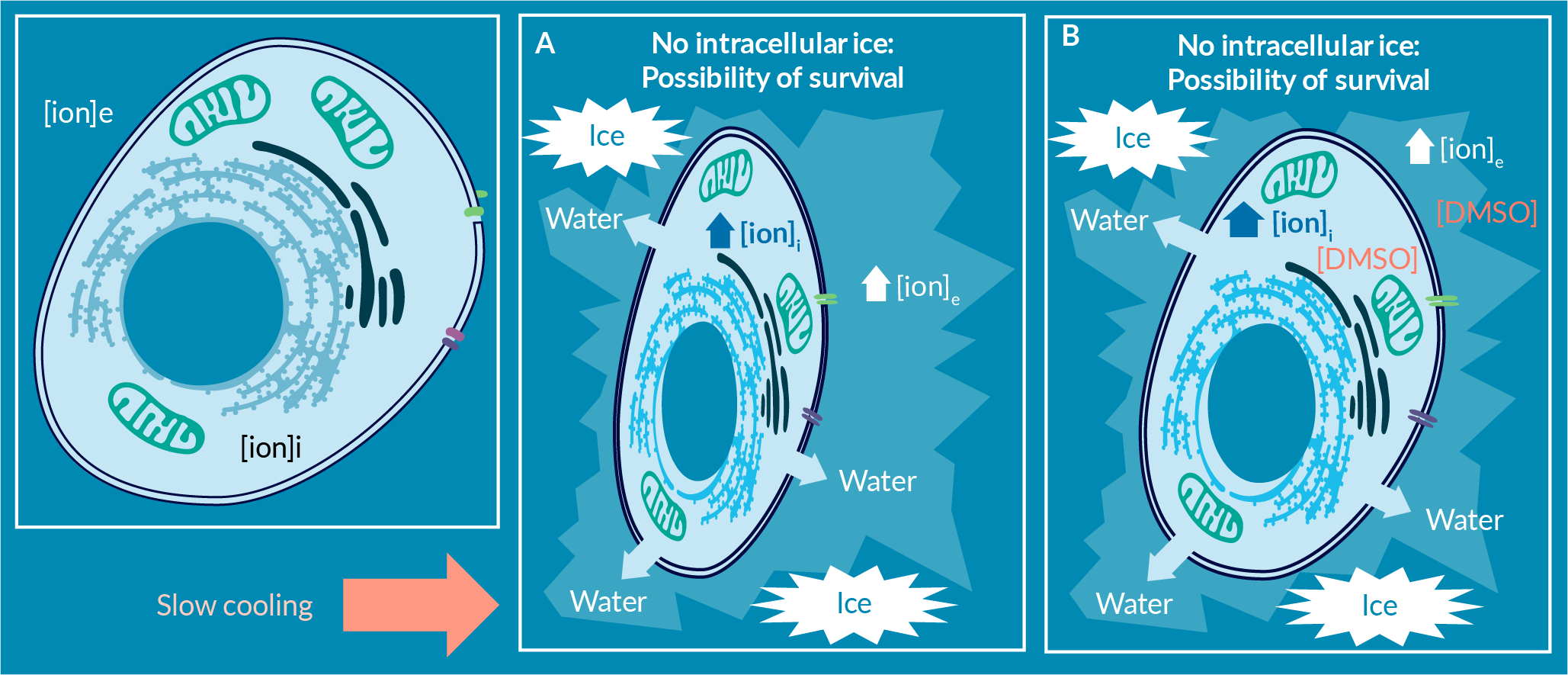

Now consider how a cell is affected by this freezing process, in the context of manufacturing a cell-based product: A slow freezing rate will allow the cells to respond osmotically to the ever-increasing osmolality of the extracellular milieu by losing water and shrinking in size (Figure 4

Osmotic shrinking, as a result of low temperatures and the cellular environment, is a dynamic process. As such, a fast freezing rate may not allow sufficient time for the cell to dehydrate enough water, and therefore increases the probability of intracellular ice formation [5]Hawkins BJ, Abazari A, Mathew AJ. Biopreservation Best Practices for regenerative medicine GMP manufacturing & focus on optimized biopreservation media. Cell Gene Ther. Ins. 2017; 3(5): 345–58. Hawkins BJ, Abazari A, Mathew AJ. Biopreservation Best Practices for regenerative medicine GMP manufacturing & focus on optimized biopreservation media. Cell Gene Ther. Ins. 2017; 3(5): 345–58. Hawkins BJ, Abazari A, Mathew AJ. Biopreservation Best Practices for regenerative medicine GMP manufacturing & focus on optimized biopreservation media. Cell Gene Ther. Ins. 2017; 3(5): 345–58. Hawkins BJ, Abazari A, Mathew AJ. Biopreservation Best Practices for regenerative medicine GMP manufacturing & focus on optimized biopreservation media. Cell Gene Ther. Ins. 2017; 3(5): 345–58. Hawkins BJ, Abazari A, Mathew AJ. Biopreservation Best Practices for regenerative medicine GMP manufacturing & focus on optimized biopreservation media. Cell Gene Ther. Ins. 2017; 3(5): 345–58. Hawkins BJ, Abazari A, Mathew AJ. Biopreservation Best Practices for regenerative medicine GMP manufacturing & focus on optimized biopreservation media. Cell Gene Ther. Ins. 2017; 3(5): 345–58. Hawkins BJ, Abazari A, Mathew AJ. Biopreservation Best Practices for regenerative medicine GMP manufacturing & focus on optimized biopreservation media. Cell Gene Ther. Ins. 2017; 3(5): 345–58. Hawkins BJ, Abazari A, Mathew AJ. Biopreservation Best Practices for regenerative medicine GMP manufacturing & focus on optimized biopreservation media. Cell Gene Ther. Ins. 2017; 3(5): 345–58. Hawkins BJ, Abazari A, Mathew AJ. Biopreservation Best Practices for regenerative medicine GMP manufacturing & focus on optimized biopreservation media. Cell Gene Ther. Ins. 2017; 3(5): 345–58. Hawkins BJ, Abazari A, Mathew AJ. Biopreservation Best Practices for regenerative medicine GMP manufacturing & focus on optimized biopreservation media. Cell Gene Ther. Ins. 2017; 3(5): 345–58. Hawkins BJ, Abazari A, Mathew AJ. Biopreservation Best Practices for regenerative medicine GMP manufacturing & focus on optimized biopreservation media. Cell Gene Ther. Ins. 2017; 3(5): 345–58. Hawkins BJ, Abazari A, Mathew AJ. Biopreservation Best Practices for regenerative medicine GMP manufacturing & focus on optimized biopreservation media. Cell Gene Ther. Ins. 2017; 3(5): 345–58. Hawkins BJ, Abazari A, Mathew AJ. Biopreservation Best Practices for regenerative medicine GMP manufacturing & focus on optimized biopreservation media. Cell Gene Ther. Ins. 2017; 3(5): 345–58. Hawkins BJ, Abazari A, Mathew AJ. Biopreservation Best Practices for regenerative medicine GMP manufacturing & focus on optimized biopreservation media. Cell Gene Ther. Ins. 2017; 3(5): 345–58. Hawkins BJ, Abazari A, Mathew AJ. Biopreservation Best Practices for regenerative medicine GMP manufacturing & focus on optimized biopreservation media. Cell Gene Ther. Ins. 2017; 3(5): 345–58. Hawkins BJ, Abazari A, Mathew AJ. Biopreservation Best Practices for regenerative medicine GMP manufacturing & focus on optimized biopreservation media. Cell Gene Ther. Ins. 2017; 3(5): 345–58. , [8]Abazari A. Process development considerations for cryopreservation of cellular therapies. Cell Gene Ther. Ins. 2019; 5(9): 1151–67.Abazari A. Process development considerations for cryopreservation of cellular therapies. Cell Gene Ther. Ins. 2019; 5(9): 1151–67.Abazari A. Process development considerations for cryopreservation of cellular therapies. Cell Gene Ther. Ins. 2019; 5(9): 1151–67.Abazari A. Process development considerations for cryopreservation of cellular therapies. Cell Gene Ther. Ins. 2019; 5(9): 1151–67.Abazari A. Process development considerations for cryopreservation of cellular therapies. Cell Gene Ther. Ins. 2019; 5(9): 1151–67.Abazari A. Process development considerations for cryopreservation of cellular therapies. Cell Gene Ther. Ins. 2019; 5(9): 1151–67.Abazari A. Process development considerations for cryopreservation of cellular therapies. Cell Gene Ther. Ins. 2019; 5(9): 1151–67.Abazari A. Process development considerations for cryopreservation of cellular therapies. Cell Gene Ther. Ins. 2019; 5(9): 1151–67.Abazari A. Process development considerations for cryopreservation of cellular therapies. Cell Gene Ther. Ins. 2019; 5(9): 1151–67., [9]Abazari A. Implementation of Biopreservation Best Practices to address a critical component of cell and gene therapy manufacturing: https://insights.bio/cell-and-gene-therapy-insights/implementation-of-biopreservation-best-practices-to-address-a-critical-component-of-cell-and-gene-therapy-manufacturing Abazari A. Implementation of Biopreservation Best Practices to address a critical component of cell and gene therapy manufacturing: https://insights.bio/cell-and-gene-therapy-insights/implementation-of-biopreservation-best-practices-to-address-a-critical-component-of-cell-and-gene-therapy-manufacturing Abazari A. Implementation of Biopreservation Best Practices to address a critical component of cell and gene therapy manufacturing: https://insights.bio/cell-and-gene-therapy-insights/implementation-of-biopreservation-best-practices-to-address-a-critical-component-of-cell-and-gene-therapy-manufacturing Abazari A. Implementation of Biopreservation Best Practices to address a critical component of cell and gene therapy manufacturing: https://insights.bio/cell-and-gene-therapy-insights/implementation-of-biopreservation-best-practices-to-address-a-critical-component-of-cell-and-gene-therapy-manufacturing Abazari A. Implementation of Biopreservation Best Practices to address a critical component of cell and gene therapy manufacturing: https://insights.bio/cell-and-gene-therapy-insights/implementation-of-biopreservation-best-practices-to-address-a-critical-component-of-cell-and-gene-therapy-manufacturing Abazari A. Implementation of Biopreservation Best Practices to address a critical component of cell and gene therapy manufacturing: https://insights.bio/cell-and-gene-therapy-insights/implementation-of-biopreservation-best-practices-to-address-a-critical-component-of-cell-and-gene-therapy-manufacturing Abazari A. Implementation of Biopreservation Best Practices to address a critical component of cell and gene therapy manufacturing: https://insights.bio/cell-and-gene-therapy-insights/implementation-of-biopreservation-best-practices-to-address-a-critical-component-of-cell-and-gene-therapy-manufacturing Abazari A. Implementation of Biopreservation Best Practices to address a critical component of cell and gene therapy manufacturing: https://insights.bio/cell-and-gene-therapy-insights/implementation-of-biopreservation-best-practices-to-address-a-critical-component-of-cell-and-gene-therapy-manufacturing Abazari A. Implementation of Biopreservation Best Practices to address a critical component of cell and gene therapy manufacturing: https://insights.bio/cell-and-gene-therapy-insights/implementation-of-biopreservation-best-practices-to-address-a-critical-component-of-cell-and-gene-therapy-manufacturing Abazari A. Implementation of Biopreservation Best Practices to address a critical component of cell and gene therapy manufacturing: https://insights.bio/cell-and-gene-therapy-insights/implementation-of-biopreservation-best-practices-to-address-a-critical-component-of-cell-and-gene-therapy-manufacturing Abazari A. Implementation of Biopreservation Best Practices to address a critical component of cell and gene therapy manufacturing: https://insights.bio/cell-and-gene-therapy-insights/implementation-of-biopreservation-best-practices-to-address-a-critical-component-of-cell-and-gene-therapy-manufacturing .

Growth of intracellular ice can physically rupture membranes. In the case of fast freezing rates, the cell may be lysed if the amount of ice is excessive, or may be damaged beyond repair even with lesser amounts of intracellular ice [5]Hawkins BJ, Abazari A, Mathew AJ. Biopreservation Best Practices for regenerative medicine GMP manufacturing & focus on optimized biopreservation media. Cell Gene Ther. Ins. 2017; 3(5): 345–58. Hawkins BJ, Abazari A, Mathew AJ. Biopreservation Best Practices for regenerative medicine GMP manufacturing & focus on optimized biopreservation media. Cell Gene Ther. Ins. 2017; 3(5): 345–58. Hawkins BJ, Abazari A, Mathew AJ. Biopreservation Best Practices for regenerative medicine GMP manufacturing & focus on optimized biopreservation media. Cell Gene Ther. Ins. 2017; 3(5): 345–58. Hawkins BJ, Abazari A, Mathew AJ. Biopreservation Best Practices for regenerative medicine GMP manufacturing & focus on optimized biopreservation media. Cell Gene Ther. Ins. 2017; 3(5): 345–58. Hawkins BJ, Abazari A, Mathew AJ. Biopreservation Best Practices for regenerative medicine GMP manufacturing & focus on optimized biopreservation media. Cell Gene Ther. Ins. 2017; 3(5): 345–58. Hawkins BJ, Abazari A, Mathew AJ. Biopreservation Best Practices for regenerative medicine GMP manufacturing & focus on optimized biopreservation media. Cell Gene Ther. Ins. 2017; 3(5): 345–58. Hawkins BJ, Abazari A, Mathew AJ. Biopreservation Best Practices for regenerative medicine GMP manufacturing & focus on optimized biopreservation media. Cell Gene Ther. Ins. 2017; 3(5): 345–58. Hawkins BJ, Abazari A, Mathew AJ. Biopreservation Best Practices for regenerative medicine GMP manufacturing & focus on optimized biopreservation media. Cell Gene Ther. Ins. 2017; 3(5): 345–58. Hawkins BJ, Abazari A, Mathew AJ. Biopreservation Best Practices for regenerative medicine GMP manufacturing & focus on optimized biopreservation media. Cell Gene Ther. Ins. 2017; 3(5): 345–58. Hawkins BJ, Abazari A, Mathew AJ. Biopreservation Best Practices for regenerative medicine GMP manufacturing & focus on optimized biopreservation media. Cell Gene Ther. Ins. 2017; 3(5): 345–58. Hawkins BJ, Abazari A, Mathew AJ. Biopreservation Best Practices for regenerative medicine GMP manufacturing & focus on optimized biopreservation media. Cell Gene Ther. Ins. 2017; 3(5): 345–58. Hawkins BJ, Abazari A, Mathew AJ. Biopreservation Best Practices for regenerative medicine GMP manufacturing & focus on optimized biopreservation media. Cell Gene Ther. Ins. 2017; 3(5): 345–58. Hawkins BJ, Abazari A, Mathew AJ. Biopreservation Best Practices for regenerative medicine GMP manufacturing & focus on optimized biopreservation media. Cell Gene Ther. Ins. 2017; 3(5): 345–58. Hawkins BJ, Abazari A, Mathew AJ. Biopreservation Best Practices for regenerative medicine GMP manufacturing & focus on optimized biopreservation media. Cell Gene Ther. Ins. 2017; 3(5): 345–58. Hawkins BJ, Abazari A, Mathew AJ. Biopreservation Best Practices for regenerative medicine GMP manufacturing & focus on optimized biopreservation media. Cell Gene Ther. Ins. 2017; 3(5): 345–58. Hawkins BJ, Abazari A, Mathew AJ. Biopreservation Best Practices for regenerative medicine GMP manufacturing & focus on optimized biopreservation media. Cell Gene Ther. Ins. 2017; 3(5): 345–58. , [8]Abazari A. Process development considerations for cryopreservation of cellular therapies. Cell Gene Ther. Ins. 2019; 5(9): 1151–67.Abazari A. Process development considerations for cryopreservation of cellular therapies. Cell Gene Ther. Ins. 2019; 5(9): 1151–67.Abazari A. Process development considerations for cryopreservation of cellular therapies. Cell Gene Ther. Ins. 2019; 5(9): 1151–67.Abazari A. Process development considerations for cryopreservation of cellular therapies. Cell Gene Ther. Ins. 2019; 5(9): 1151–67.Abazari A. Process development considerations for cryopreservation of cellular therapies. Cell Gene Ther. Ins. 2019; 5(9): 1151–67.Abazari A. Process development considerations for cryopreservation of cellular therapies. Cell Gene Ther. Ins. 2019; 5(9): 1151–67.Abazari A. Process development considerations for cryopreservation of cellular therapies. Cell Gene Ther. Ins. 2019; 5(9): 1151–67.Abazari A. Process development considerations for cryopreservation of cellular therapies. Cell Gene Ther. Ins. 2019; 5(9): 1151–67.Abazari A. Process development considerations for cryopreservation of cellular therapies. Cell Gene Ther. Ins. 2019; 5(9): 1151–67., [9]Abazari A. Implementation of Biopreservation Best Practices to address a critical component of cell and gene therapy manufacturing: https://insights.bio/cell-and-gene-therapy-insights/implementation-of-biopreservation-best-practices-to-address-a-critical-component-of-cell-and-gene-therapy-manufacturing Abazari A. Implementation of Biopreservation Best Practices to address a critical component of cell and gene therapy manufacturing: https://insights.bio/cell-and-gene-therapy-insights/implementation-of-biopreservation-best-practices-to-address-a-critical-component-of-cell-and-gene-therapy-manufacturing Abazari A. Implementation of Biopreservation Best Practices to address a critical component of cell and gene therapy manufacturing: https://insights.bio/cell-and-gene-therapy-insights/implementation-of-biopreservation-best-practices-to-address-a-critical-component-of-cell-and-gene-therapy-manufacturing Abazari A. Implementation of Biopreservation Best Practices to address a critical component of cell and gene therapy manufacturing: https://insights.bio/cell-and-gene-therapy-insights/implementation-of-biopreservation-best-practices-to-address-a-critical-component-of-cell-and-gene-therapy-manufacturing Abazari A. Implementation of Biopreservation Best Practices to address a critical component of cell and gene therapy manufacturing: https://insights.bio/cell-and-gene-therapy-insights/implementation-of-biopreservation-best-practices-to-address-a-critical-component-of-cell-and-gene-therapy-manufacturing Abazari A. Implementation of Biopreservation Best Practices to address a critical component of cell and gene therapy manufacturing: https://insights.bio/cell-and-gene-therapy-insights/implementation-of-biopreservation-best-practices-to-address-a-critical-component-of-cell-and-gene-therapy-manufacturing Abazari A. Implementation of Biopreservation Best Practices to address a critical component of cell and gene therapy manufacturing: https://insights.bio/cell-and-gene-therapy-insights/implementation-of-biopreservation-best-practices-to-address-a-critical-component-of-cell-and-gene-therapy-manufacturing Abazari A. Implementation of Biopreservation Best Practices to address a critical component of cell and gene therapy manufacturing: https://insights.bio/cell-and-gene-therapy-insights/implementation-of-biopreservation-best-practices-to-address-a-critical-component-of-cell-and-gene-therapy-manufacturing Abazari A. Implementation of Biopreservation Best Practices to address a critical component of cell and gene therapy manufacturing: https://insights.bio/cell-and-gene-therapy-insights/implementation-of-biopreservation-best-practices-to-address-a-critical-component-of-cell-and-gene-therapy-manufacturing Abazari A. Implementation of Biopreservation Best Practices to address a critical component of cell and gene therapy manufacturing: https://insights.bio/cell-and-gene-therapy-insights/implementation-of-biopreservation-best-practices-to-address-a-critical-component-of-cell-and-gene-therapy-manufacturing Abazari A. Implementation of Biopreservation Best Practices to address a critical component of cell and gene therapy manufacturing: https://insights.bio/cell-and-gene-therapy-insights/implementation-of-biopreservation-best-practices-to-address-a-critical-component-of-cell-and-gene-therapy-manufacturing .

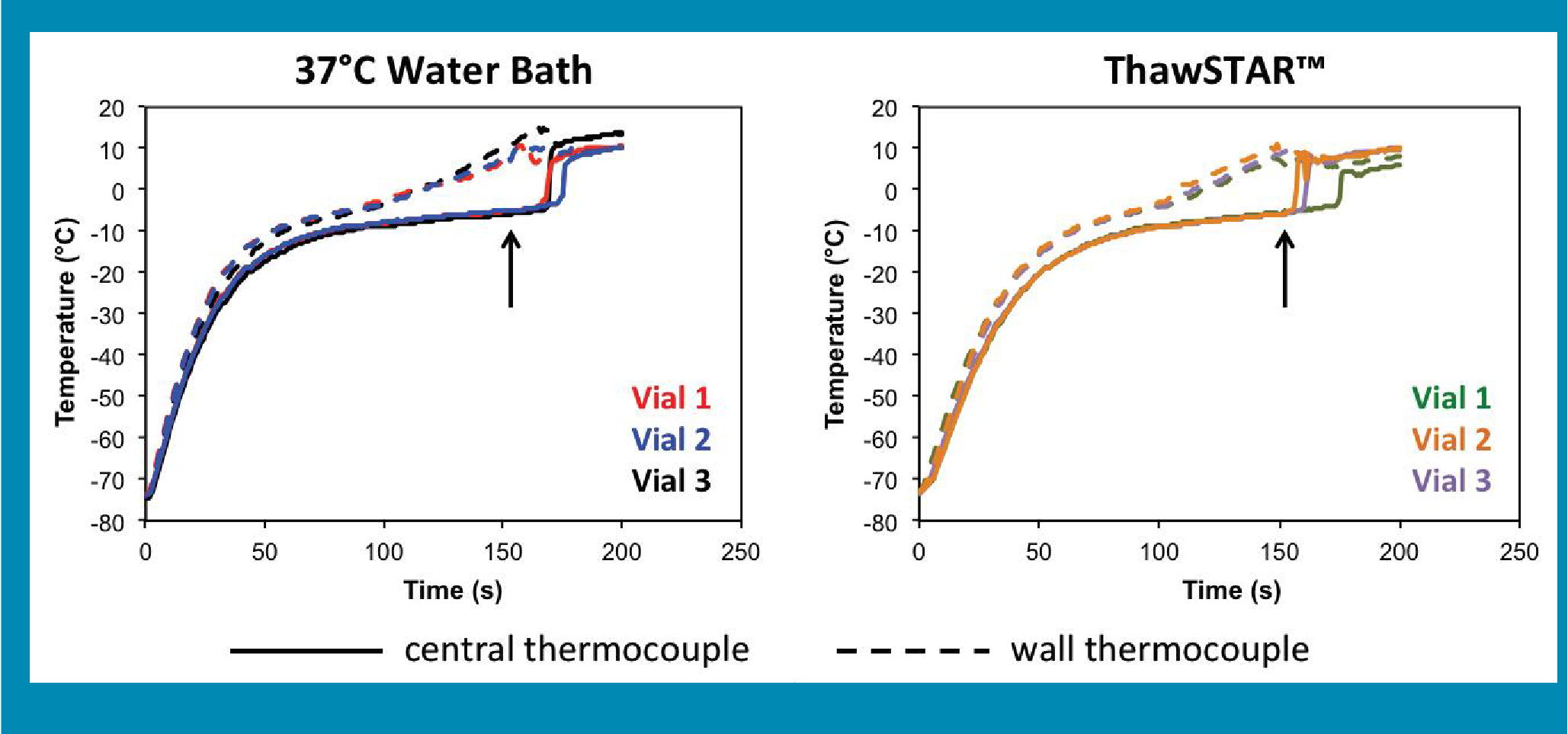

In general, freezing rates around -1°C/min or so are observed to allow water-membrane dynamics to dehydrate CGT-relevant cell types sufficiently to reduce intracellular ice formation (Figure 5A). However, the level of osmotically-induced volume shrinkage may reach as low as 30% of the original cell volume. This may result in other forms of physical damage – including membrane folding and fusion, which is generally observed in the form of lower average cell volume, and an increase in the number of small non-cell vesicles post-thaw. The toxicity due to orders-of-magnitude increase in salinity, combined with mechanical cues from excessive osmotic shrinkage, induce adverse events in cells. These forms of cell damage and cell death include acute necrosis; and later Delayed Onset Cell Death (that becomes apparent as loss of viable recovery and function over hours to days post-thaw) [5]Hawkins BJ, Abazari A, Mathew AJ. Biopreservation Best Practices for regenerative medicine GMP manufacturing & focus on optimized biopreservation media. Cell Gene Ther. Ins. 2017; 3(5): 345–58. Hawkins BJ, Abazari A, Mathew AJ. Biopreservation Best Practices for regenerative medicine GMP manufacturing & focus on optimized biopreservation media. Cell Gene Ther. Ins. 2017; 3(5): 345–58. Hawkins BJ, Abazari A, Mathew AJ. Biopreservation Best Practices for regenerative medicine GMP manufacturing & focus on optimized biopreservation media. Cell Gene Ther. Ins. 2017; 3(5): 345–58. Hawkins BJ, Abazari A, Mathew AJ. Biopreservation Best Practices for regenerative medicine GMP manufacturing & focus on optimized biopreservation media. Cell Gene Ther. Ins. 2017; 3(5): 345–58. Hawkins BJ, Abazari A, Mathew AJ. Biopreservation Best Practices for regenerative medicine GMP manufacturing & focus on optimized biopreservation media. Cell Gene Ther. Ins. 2017; 3(5): 345–58. Hawkins BJ, Abazari A, Mathew AJ. Biopreservation Best Practices for regenerative medicine GMP manufacturing & focus on optimized biopreservation media. Cell Gene Ther. Ins. 2017; 3(5): 345–58. Hawkins BJ, Abazari A, Mathew AJ. Biopreservation Best Practices for regenerative medicine GMP manufacturing & focus on optimized biopreservation media. Cell Gene Ther. Ins. 2017; 3(5): 345–58. Hawkins BJ, Abazari A, Mathew AJ. Biopreservation Best Practices for regenerative medicine GMP manufacturing & focus on optimized biopreservation media. Cell Gene Ther. Ins. 2017; 3(5): 345–58. Hawkins BJ, Abazari A, Mathew AJ. Biopreservation Best Practices for regenerative medicine GMP manufacturing & focus on optimized biopreservation media. Cell Gene Ther. Ins. 2017; 3(5): 345–58. Hawkins BJ, Abazari A, Mathew AJ. Biopreservation Best Practices for regenerative medicine GMP manufacturing & focus on optimized biopreservation media. Cell Gene Ther. Ins. 2017; 3(5): 345–58. Hawkins BJ, Abazari A, Mathew AJ. Biopreservation Best Practices for regenerative medicine GMP manufacturing & focus on optimized biopreservation media. Cell Gene Ther. Ins. 2017; 3(5): 345–58. Hawkins BJ, Abazari A, Mathew AJ. Biopreservation Best Practices for regenerative medicine GMP manufacturing & focus on optimized biopreservation media. Cell Gene Ther. Ins. 2017; 3(5): 345–58. Hawkins BJ, Abazari A, Mathew AJ. Biopreservation Best Practices for regenerative medicine GMP manufacturing & focus on optimized biopreservation media. Cell Gene Ther. Ins. 2017; 3(5): 345–58. Hawkins BJ, Abazari A, Mathew AJ. Biopreservation Best Practices for regenerative medicine GMP manufacturing & focus on optimized biopreservation media. Cell Gene Ther. Ins. 2017; 3(5): 345–58. Hawkins BJ, Abazari A, Mathew AJ. Biopreservation Best Practices for regenerative medicine GMP manufacturing & focus on optimized biopreservation media. Cell Gene Ther. Ins. 2017; 3(5): 345–58. Hawkins BJ, Abazari A, Mathew AJ. Biopreservation Best Practices for regenerative medicine GMP manufacturing & focus on optimized biopreservation media. Cell Gene Ther. Ins. 2017; 3(5): 345–58. .

To reduce the osmotic shrinkage, and the toxicity due to increased solute concentration, cryoprotective agents (CPA) are added to the solution (membrane-permeable and/or non-permeating). One of the most well-known and most studied cryoprotective agents is dimethyl sulfoxide, or DMSO (Figure 5

While referred to by some as an “anti-freeze” agent, DMSO offers protection against freezing in rather complex ways. In the unfrozen fraction, DMSO reduces salinity-induced toxicity and mechanical osmotic shrinkage by engaging water molecules and preventing ice crystal growth. As such, the cells are exposed to less salinity at any given temperature with the presence of DMSO. Furthermore, by permeating the cell, DMSO reduces the cell volumetric changes during freezing and minimizes intracellular ice growth [9]Abazari A. Implementation of Biopreservation Best Practices to address a critical component of cell and gene therapy manufacturing: https://insights.bio/cell-and-gene-therapy-insights/implementation-of-biopreservation-best-practices-to-address-a-critical-component-of-cell-and-gene-therapy-manufacturing Abazari A. Implementation of Biopreservation Best Practices to address a critical component of cell and gene therapy manufacturing: https://insights.bio/cell-and-gene-therapy-insights/implementation-of-biopreservation-best-practices-to-address-a-critical-component-of-cell-and-gene-therapy-manufacturing Abazari A. Implementation of Biopreservation Best Practices to address a critical component of cell and gene therapy manufacturing: https://insights.bio/cell-and-gene-therapy-insights/implementation-of-biopreservation-best-practices-to-address-a-critical-component-of-cell-and-gene-therapy-manufacturing Abazari A. Implementation of Biopreservation Best Practices to address a critical component of cell and gene therapy manufacturing: https://insights.bio/cell-and-gene-therapy-insights/implementation-of-biopreservation-best-practices-to-address-a-critical-component-of-cell-and-gene-therapy-manufacturing Abazari A. Implementation of Biopreservation Best Practices to address a critical component of cell and gene therapy manufacturing: https://insights.bio/cell-and-gene-therapy-insights/implementation-of-biopreservation-best-practices-to-address-a-critical-component-of-cell-and-gene-therapy-manufacturing Abazari A. Implementation of Biopreservation Best Practices to address a critical component of cell and gene therapy manufacturing: https://insights.bio/cell-and-gene-therapy-insights/implementation-of-biopreservation-best-practices-to-address-a-critical-component-of-cell-and-gene-therapy-manufacturing Abazari A. Implementation of Biopreservation Best Practices to address a critical component of cell and gene therapy manufacturing: https://insights.bio/cell-and-gene-therapy-insights/implementation-of-biopreservation-best-practices-to-address-a-critical-component-of-cell-and-gene-therapy-manufacturing Abazari A. Implementation of Biopreservation Best Practices to address a critical component of cell and gene therapy manufacturing: https://insights.bio/cell-and-gene-therapy-insights/implementation-of-biopreservation-best-practices-to-address-a-critical-component-of-cell-and-gene-therapy-manufacturing Abazari A. Implementation of Biopreservation Best Practices to address a critical component of cell and gene therapy manufacturing: https://insights.bio/cell-and-gene-therapy-insights/implementation-of-biopreservation-best-practices-to-address-a-critical-component-of-cell-and-gene-therapy-manufacturing Abazari A. Implementation of Biopreservation Best Practices to address a critical component of cell and gene therapy manufacturing: https://insights.bio/cell-and-gene-therapy-insights/implementation-of-biopreservation-best-practices-to-address-a-critical-component-of-cell-and-gene-therapy-manufacturing Abazari A. Implementation of Biopreservation Best Practices to address a critical component of cell and gene therapy manufacturing: https://insights.bio/cell-and-gene-therapy-insights/implementation-of-biopreservation-best-practices-to-address-a-critical-component-of-cell-and-gene-therapy-manufacturing . This particular set of actions of DMSO may not be readily replicated by other non-permeating cryoprotective agents and sugars, or other permeating cryoprotective agents with similar efficacy.

Why cryopreserve cell-based products?

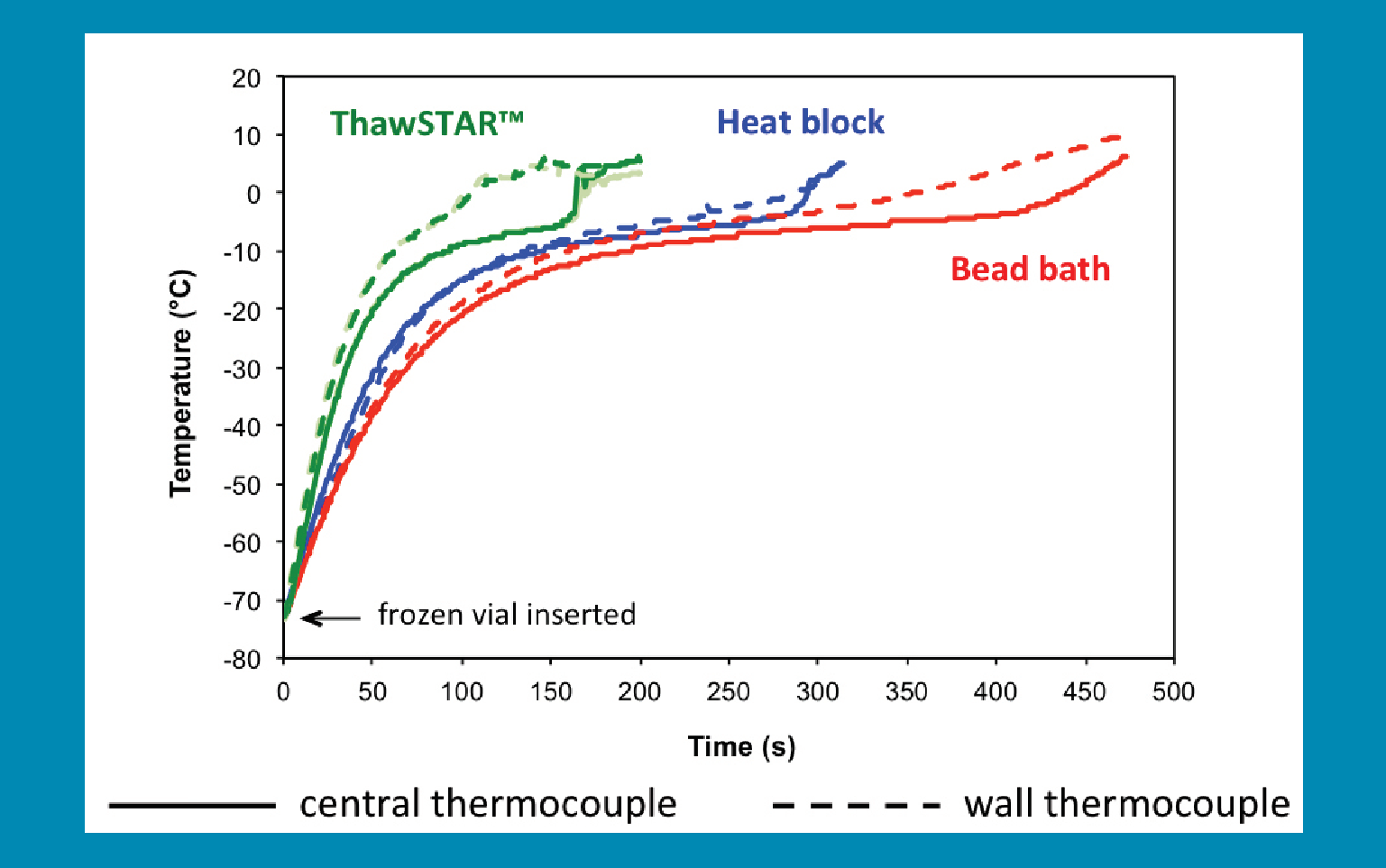

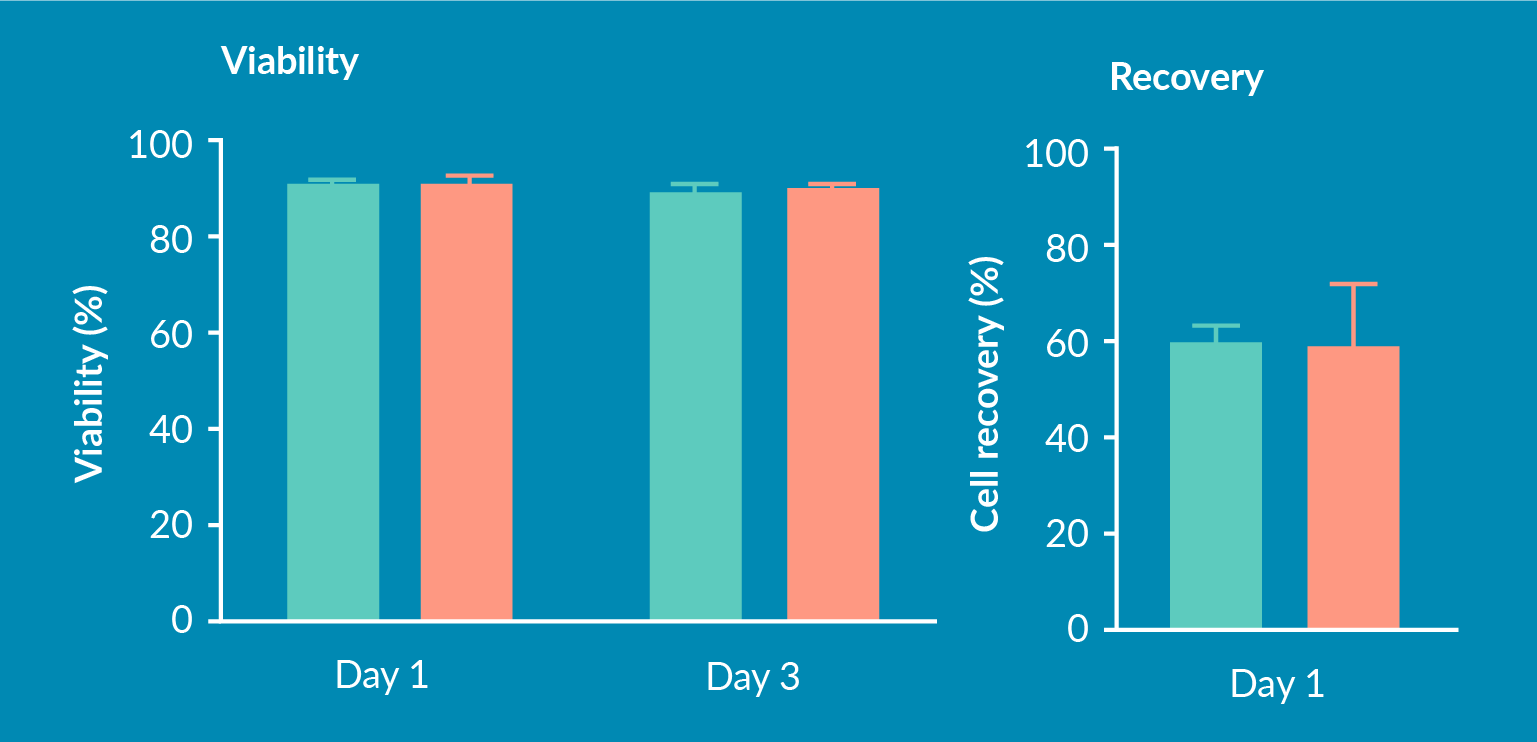

Clinical and commercial manufacturing models drive several critical aspects about the CGT process and workflow. While, in theory, “fresh” non-frozen materials may be preferred by some (if even possible/feasible) due to simplicity (no cryopreservation step, no LN2 dewar shipping step, no thawing, no documentation for cryo-related procedures, etc.), the spatial separation biologistics of source starting materials/manufacturing activities/patients, and the globalization of supply chain management, are ameliorated by the temporal time management benefits of cryopreservation.