Implementation of biopreservation best practices to address a critical component of cell and gene therapy manufacturing

We welcome your biopreservation questions any time. Please contact us at Ask the Scientists.

There is more to Biopreservation than storage on ice or freezing at a rate of -1°C/min. To comprehend the rationale behind Biopreservation Best Practices, a basic understanding of cellular response to cold and freezing is essential. This presentation will identify the critical process parameters (CPPs) of Cold Chain, such as freezing and thawing rates, storage and post-thaw stability, and container type, among others, and will discuss the impact of these CPPs on critical quality attributes (CQAs) such as viability, yield, proliferation rate, and return to function.

We also discuss how the CPPs may impact variability in assay results. In general, implementation of best practices in formulation can directly address multiple process bottlenecks including: GMP compliance, minimizing freezing damage, support stability during storage and against transient warming events, support post-thaw stability, and excipient qualification.

The CQAs may also be improved by adjusting key parameters in the freezing profile. Incorporation of Biopreservation Best Practices conveys important advantages upstream and downstream of ATMP manufacturing, including:

- Assisting in the selection of the right delivery model, i.e. fresh vs. frozen, and the specific infrastructure and personnel requirements of each, based on which a commercial model is structured

- Reducing the regulatory footprint of Cold Chain, and eliminating the burden of process changes when advancing to clinical trials

- Improving the CQAs, hence potentially improving safety and efficacy of the ATMPs in clinical trials. As such, early incorporation of Biopreservation Best Practices in ATMP manufacturing is highly recommended

Watch this on demand webinar with Alireza Abazari, MSc, PhD, Scientific Applications Director, BioLife Solutions, Inc as he discusses:

- Mechanisms of cold/freezing injury

- Impact of cold/freezing stress on cell characterization

- Strategies to mitigate cold/freezing injury

You might also like

Advancing AAV manufacturing: strategic insights and cost-effective solutions for the future of gene therapies

From concept to clinic: overcoming the challenges of potency assays in cell and gene therapy development

Understanding and leveraging cord blood bank capabilities and practices in cell therapy development

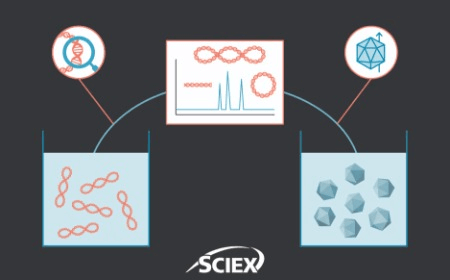

Application of CGE in cell and gene therapy