Commercial-scale manufacture of lentivirus for ex vivo and in vivo therapies

There are three key current challenges that the cell and gene therapy field is facing in the manufacture of CAR-T cells: one is raw material production, the second is the production of enough viral vector to meet demand, and the third is the inherent variability in cellular starting material. The common approach to generating fragile envelope viruses like lentiviral vectors (LVs) is based on transient transfection. LV is also produced by inducible expression system using stable producer cell lines. In this study we will present proof-of-concept studies on the development of a perfusion-intensified (by 50-fold) process for envelope virus-based vector manufacturing, providing sufficient LV to cater for large patient populations.

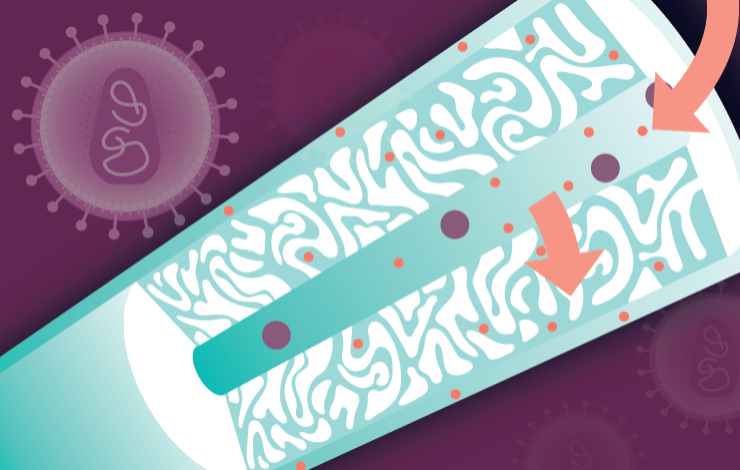

As the field of LVs is progressing toward large-scale manufacturing to generate sufficient functional lentivirus for treating patients, scalability and consistency are important aspects to consider. The TFDF perfusion system that is adapted to the fragility of envelope viruses can be scaled to industrial-size production bioreactors where the LVs are harvested continuously and pass into the TFF or capture step of downstream purification. This greatly reduces hold time, reducing loss of envelope virus functionality.

- Understanding how KrosFlo TFDF can increase productivity and yield for lentivirus manufacturing

- Improving and simplifying production and manufacturing capacity using a closed automated continuous virus harvest strategy

- Addressing scalability, yield, labor, and cost challenges in using suspension and adherent cell line platforms for large-scale continuous manufacturing of LVs using TFDF

- Developing an agnostic platform solution for envelope-based viral vector production and continuous clarification

- Targeting affordable viral vector manufacturing by reducing cost per dose

You might also like

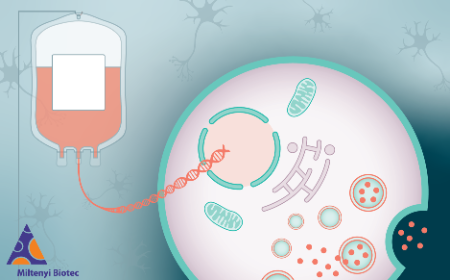

Ex vivo engineering of hematopoietic stem cells using RNA-LNPs for cell and gene therapies

Case study: developing an ex vivo gene-modified hematopoietic stem cell treatment for a rare monogenic disease in a novel mouse model

Large-scale manufacturing of allogeneic stem cell-derived NK cell therapies